Overview

- Summary

- A specialized company dedicated to the development and manufacturing of hot melt automatic spraying machines and adhesive solutions with proprietary Korean technology, supplying various industrial sites.A specialized company dedicated to the development and manufacturing of hot melt automatic spraying machines and adhesive solutions with proprietary Korean technology, supplying various industrial sites.

- Key Products/Technologies

- The hot melt automatic spraying machine is a core product line, developed domestically since 1985 and completed with the company's establishment in 1993.The hot melt automatic spraying machine is a core product line, developed domestically since 1985 and completed with the company's establishment in 1993.

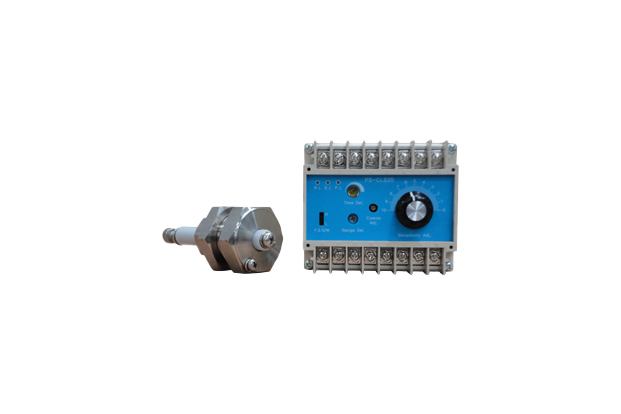

- Key product categories include modules, tanks (NINO Series, BS Series, BGS Series, APSV Series), hoses, guns, nozzles/modules, pumps, controllers, timers, and spare parts.Key product categories include modules, tanks (NINO Series, BS Series, BGS Series, APSV Series), hoses, guns, nozzles/modules, pumps, controllers, timers, and spare parts.

- Tank products encompass various models such as NINO-70, BS-10, BS-20, BS-30, BS-60, BGS-120, BGS-280, BGS-400, APSV-10, APSV-20, APSV-30, and APSV-60.Tank products encompass various models such as NINO-70, BS-10, BS-20, BS-30, BS-60, BGS-120, BGS-280, BGS-400, APSV-10, APSV-20, APSV-30, and APSV-60.

- Among module products, the 730400 and Zero Cavity Module offer excellent hot melt interception capabilities through direct nozzle and needle linkage, ensuring precise spray pattern control.Among module products, the 730400 and Zero Cavity Module offer excellent hot melt interception capabilities through direct nozzle and needle linkage, ensuring precise spray pattern control.

- Controllers, specifically the microprocessor-based TCS-300 and TCS-200 temperature controllers, regulate up to six temperature zones with standby temperature settings and automatic error checking functions.Controllers, specifically the microprocessor-based TCS-300 and TCS-200 temperature controllers, regulate up to six temperature zones with standby temperature settings and automatic error checking functions.

- Gun products include the Slot Die Gun, capable of line injection or coding over widths exceeding 700mm, and the Multi Line Gun, featuring individual flow control capabilities.Gun products include the Slot Die Gun, capable of line injection or coding over widths exceeding 700mm, and the Multi Line Gun, featuring individual flow control capabilities.

- The company produces two types of injection equipment: electrical solenoid and air-operated valve systems, demonstrating expertise in high-viscosity and high-pressure hot melt adhesive applications.The company produces two types of injection equipment: electrical solenoid and air-operated valve systems, demonstrating expertise in high-viscosity and high-pressure hot melt adhesive applications.

- Designed for easy replacement of all parts, enhancing maintenance convenience, with electrical components connected via connectors.Designed for easy replacement of all parts, enhancing maintenance convenience, with electrical components connected via connectors.

- Core Advantages

- Superior price competitiveness compared to foreign products, contributing to cost reduction for client companies.Superior price competitiveness compared to foreign products, contributing to cost reduction for client companies.

- Ease of parts supply and prompt after-sales service capabilities due to domestic development.Ease of parts supply and prompt after-sales service capabilities due to domestic development.

- Continuous improvement of machine performance based on extensive accumulated manufacturing and operational experience.Continuous improvement of machine performance based on extensive accumulated manufacturing and operational experience.

- Provision of customized solutions tailored to customer requirements and continuous R&D investment for new product development.Provision of customized solutions tailored to customer requirements and continuous R&D investment for new product development.

- Precise temperature control and flow regulation technology based on microprocessors, ensuring stable hot melt spraying performance.Precise temperature control and flow regulation technology based on microprocessors, ensuring stable hot melt spraying performance.

- Utilization of solvent-free, non-flammable, non-volatile thermoplastic hot melt adhesives, promoting environmental friendliness, high-speed operation, and superior working efficiency.Utilization of solvent-free, non-flammable, non-volatile thermoplastic hot melt adhesives, promoting environmental friendliness, high-speed operation, and superior working efficiency.

- Target Industrie

- General manufacturing industry for adhesion and coating processes.General manufacturing industry for adhesion and coating processes.

- Packaging industry for box adhesion and sealing.Packaging industry for box adhesion and sealing.

- Automotive industry for component assembly and bonding.Automotive industry for component assembly and bonding.

- Electronics assembly industry for precision bonding.Electronics assembly industry for precision bonding.

- Bookbinding processes for book production and quality enhancement.Bookbinding processes for book production and quality enhancement.

- Major Markets

- China, JapanChina, Japan

- Certifications/Patents

- Acquisition of Clean Industry certification in 2006.Acquisition of Clean Industry certification in 2006.

- Obtainment of a patent for water-based adhesive injection devices in 2007.Obtainment of a patent for water-based adhesive injection devices in 2007.

- Achievement of NINO, FBS, and CE certifications in 2012.Achievement of NINO, FBS, and CE certifications in 2012.

- Awarded the Export Tower in 2012, demonstrating competitiveness in international markets.Awarded the Export Tower in 2012, demonstrating competitiveness in international markets.

Introduction

Location

62 Dangjeong-ro, Gunpo-si, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기