This product is manufactured by

NEOS

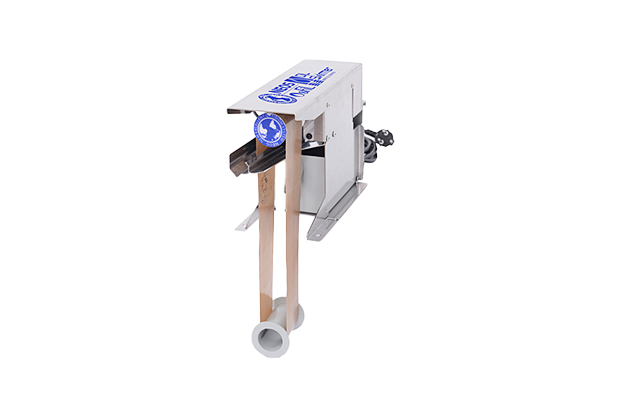

Oil Skimmer & Separator (Built in Type (Economic))

Model Name

OsFil-EB

Data

-

Manufacturer information

NEOS

Oil skimmer, Oil separator, Magnetic separator, Paper filter, Cutting fluid cleaning system, Electronic valve, NEOS

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

NEOS

Product Type

Machine

Brand

-

SKU

134758

Product Name

Oil Skimmer & Separator (Built in Type (Economic))

Model Name

OsFil-EB

Size

-

Weight

-

Product Details

More products

Return FilterR-160, R-250, R-400

쿨란트 탱크 이동형 청소기OsFiL-P-80-300, OsFiL-P-80-600, OsFiL-P-80-900, OsFiL-M-250-300

하이브리드 필터링 시스템

커터 임펠라 펌프

폐유(윤활유,절삭유,유압유,방청유) 정제시스템

스컴 스키머, 유수 분리기

Water & Oil SeparatorOsFil-Separator Tank

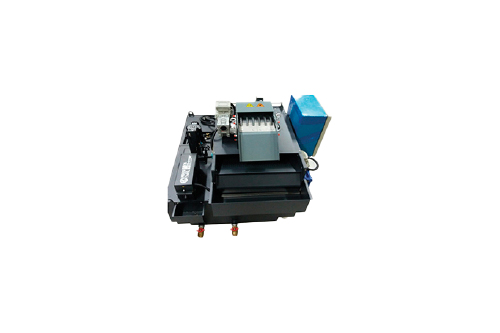

Oil Skimmer & Separator (Built in Type)OsFil-B

Oil Skimmer & Separator (Mobile Type (Economic))OsFiL-EM

Oil Skimmer & Separator (Mobile Type)OsFiL-M

Oil Skimmer & Separator (Belt Type)OsFiL B-65

하이브리드 필터링 시스템

하이브리드 필터링 시스템

하이브리드 필터링 시스템

하이브리드 필터링 시스템

1/4