This product is manufactured by

LSMtron Injection Machine

Manufacturer information

LSMtron Injection Machine

Injection Machine Manufacturer

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

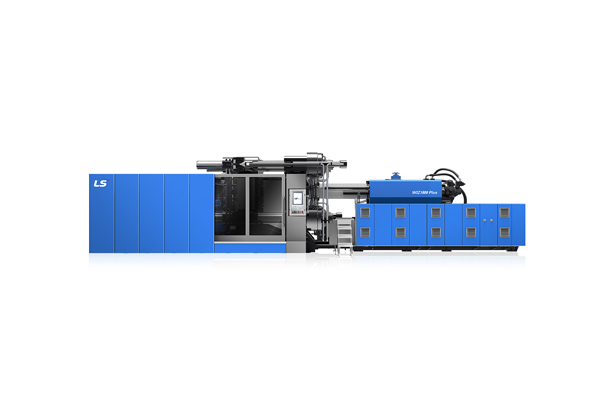

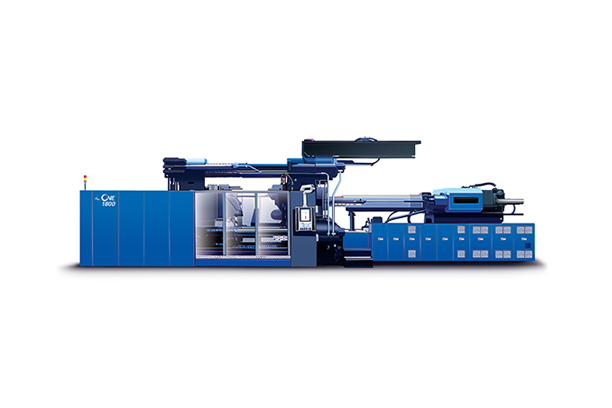

LSMtron Injection Machine

Product Type

Machine

Brand

-

SKU

140110

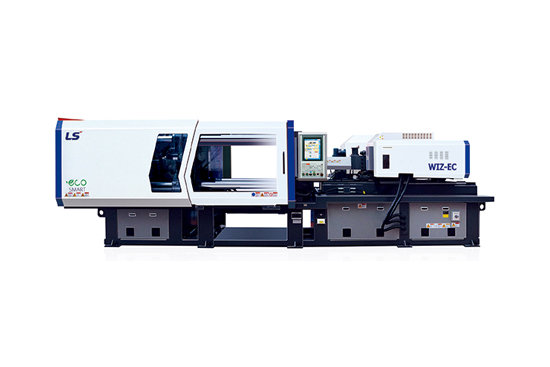

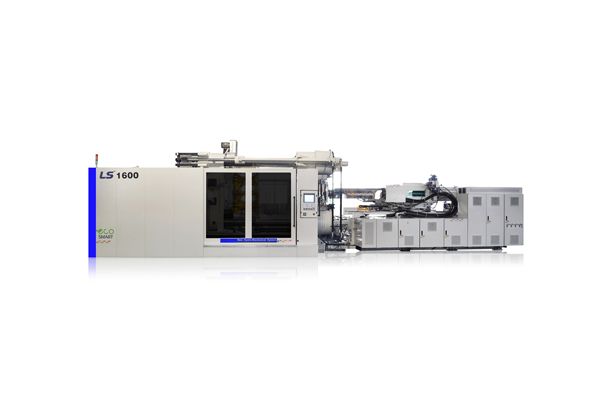

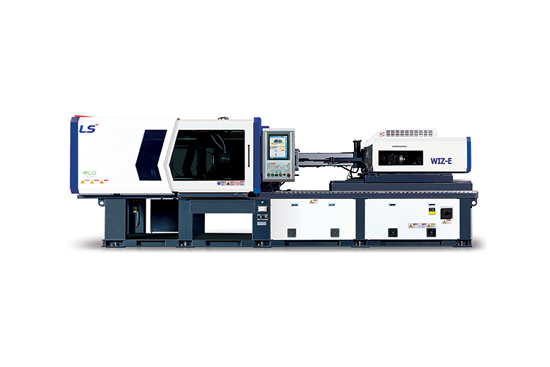

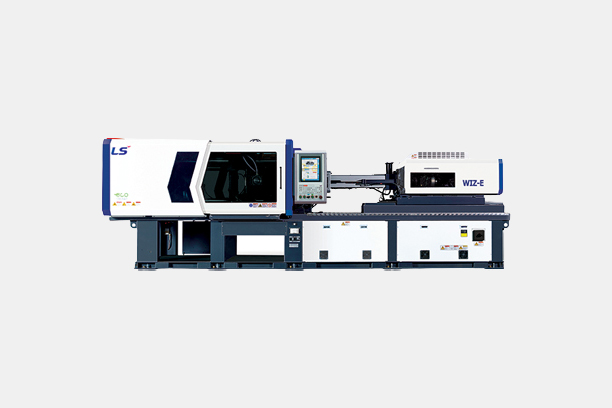

Product Name

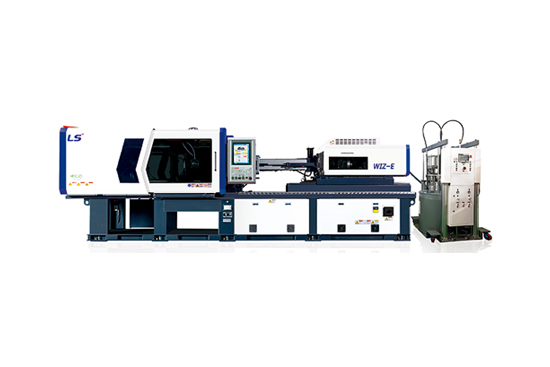

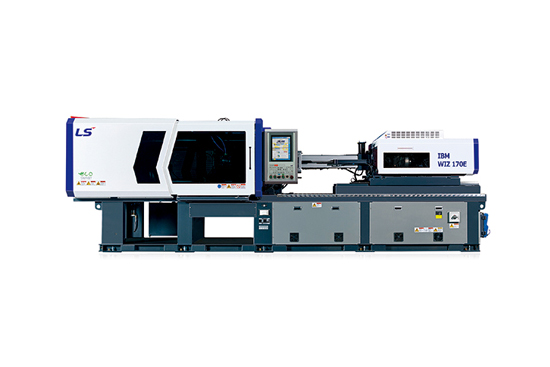

WIZ-E LSR Series

Model Name

-

Size

-

Weight

-

Product Details