This product is manufactured by

LEMO S.A.

Manufacturer information

LEMO S.A.

Manufacturer of Push-Pull Connector, Precision Custom Connection and Cable Solutions

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

LEMO S.A.

Product Type

Machine

Brand

-

SKU

141643

Product Name

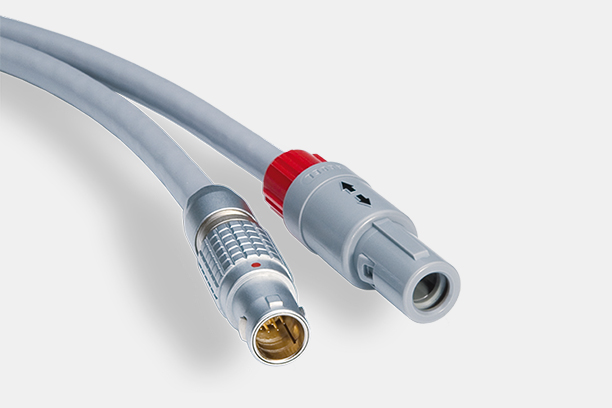

LEMO B-Series Push Pull Connector

Model Name

-

Size

-

Weight

-

Product Details

More products