This product is manufactured by

KORLOY

Manufacturer information

KORLOY

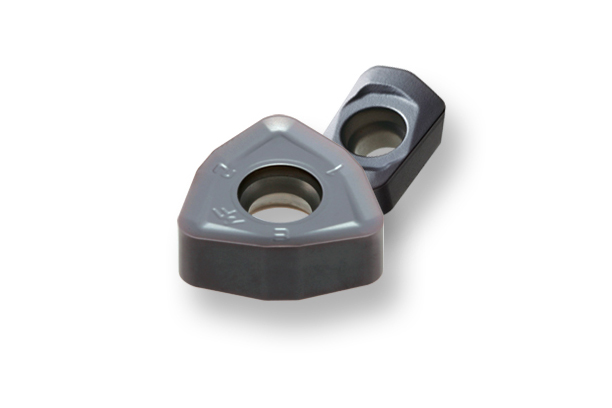

Hard metal tools manufacturer, Insert, End mill, Drill, Tool holder, Boring bar, Carter body

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

KORLOY

Product Type

Machine

Brand

-

SKU

137346

Product Name

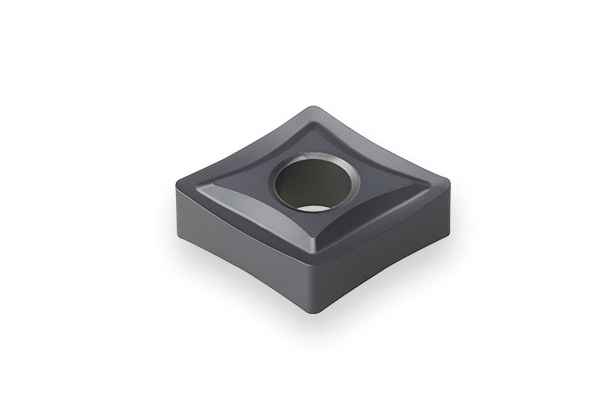

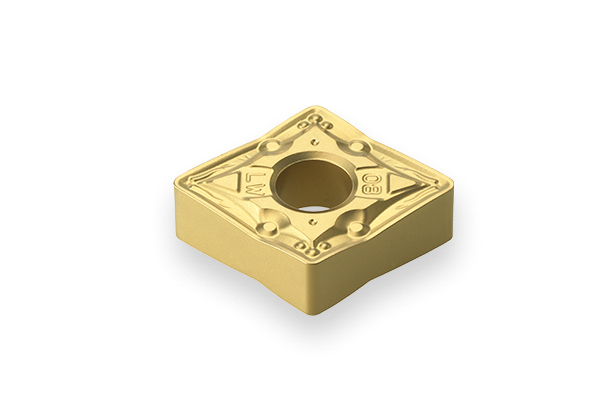

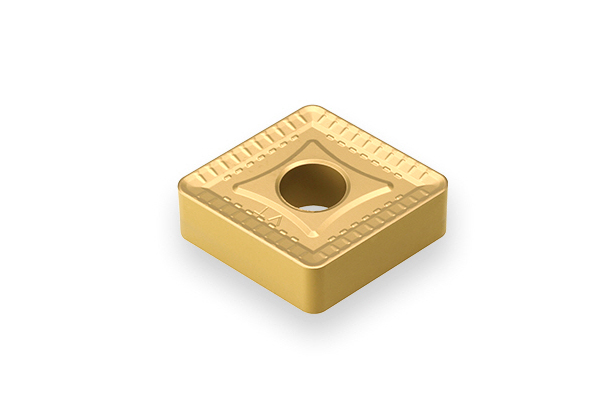

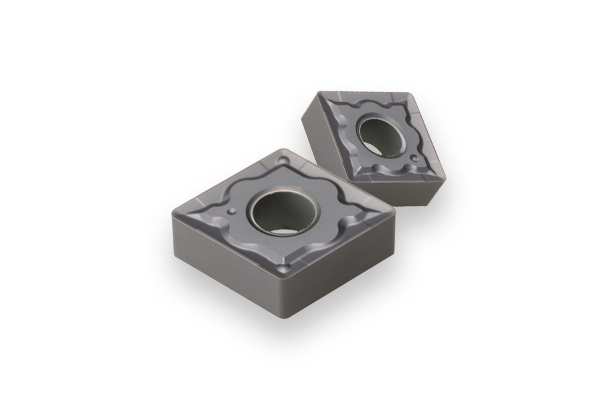

Chip Breaker

Model Name

VP

Size

-

Weight

-

Product Details