Overview

- Summary

- KM Digitech is a specialized enterprise leading the Korean harness equipment market for over 30 years. The company has established a strong position in the domestic market through the development and supply of innovative and creative harness equipment and solutions. With the launch of the LIMS automatic crimping machine and new applicators in 2016, its technological capabilities are further enhanced. The company is laying the groundwork for becoming a world-class enterprise beyond its domestic leadership. A company dedicated to continuous research and development, aiming for the localization and smartification of wire processing automation facilities.KM Digitech is a specialized enterprise leading the Korean harness equipment market for over 30 years. The company has established a strong position in the domestic market through the development and supply of innovative and creative harness equipment and solutions. With the launch of the LIMS automatic crimping machine and new applicators in 2016, its technological capabilities are further enhanced. The company is laying the groundwork for becoming a world-class enterprise beyond its domestic leadership. A company dedicated to continuous research and development, aiming for the localization and smartification of wire processing automation facilities.

- Key Products/Technologies

- The LIMS-A1 fully automatic crimping machine is a new model efficiently handling the entire wire processing sequence, from wire feeding, cutting, stripping, crimping, seal insertion, to wire receiving. It boasts a maximum feeding motor speed of 7,000mm/sec and a crimping capacity of 4 tons, incorporating Piezo sensor-based crimping management and laser sensor stripping detection. Real-time length correction via encoder and network communication support for ERP integration are key features.The LIMS-A1 fully automatic crimping machine is a new model efficiently handling the entire wire processing sequence, from wire feeding, cutting, stripping, crimping, seal insertion, to wire receiving. It boasts a maximum feeding motor speed of 7,000mm/sec and a crimping capacity of 4 tons, incorporating Piezo sensor-based crimping management and laser sensor stripping detection. Real-time length correction via encoder and network communication support for ERP integration are key features.

- The LIMS-P1B fully automatic crimping machine features a belt feeding system, ensuring stable processing of wires from thin to thick with minimal length deviation. It offers an auto-height system for automatic crimping height adjustment as a standard feature, and a laser stripping sensor guarantees a 100% detection rate without damaging the core wire. Digital control of air pressure for the wire feeding section and linkage with external I/O devices like barcode scanners and label printers are also available.The LIMS-P1B fully automatic crimping machine features a belt feeding system, ensuring stable processing of wires from thin to thick with minimal length deviation. It offers an auto-height system for automatic crimping height adjustment as a standard feature, and a laser stripping sensor guarantees a 100% detection rate without damaging the core wire. Digital control of air pressure for the wire feeding section and linkage with external I/O devices like barcode scanners and label printers are also available.

- The KM-702N digital wire stripping machine processes wires ranging from AWG12 to AWG30, featuring an Auto Strip Sensor for automatic blade value setting based on core wire thickness. It utilizes 5-line blades for increased productivity and up to five times longer blade life, with an automatic roller lifting mechanism after stripping to prevent core wire damage. 100 memory slots and various sensors provide a precise and stable working environment.The KM-702N digital wire stripping machine processes wires ranging from AWG12 to AWG30, featuring an Auto Strip Sensor for automatic blade value setting based on core wire thickness. It utilizes 5-line blades for increased productivity and up to five times longer blade life, with an automatic roller lifting mechanism after stripping to prevent core wire damage. 100 memory slots and various sensors provide a precise and stable working environment.

- The KM-3300 automatic cutting machine precisely and rapidly cuts various materials such as tubes, insulation paper, film, wire, copper plates, and hoses, up to 300mm in width. It includes easy function settings via a digital screen, 5 memory slots, and cutting speed adjustment. Optional features like a material feeder and static electricity remover are available.The KM-3300 automatic cutting machine precisely and rapidly cuts various materials such as tubes, insulation paper, film, wire, copper plates, and hoses, up to 300mm in width. It includes easy function settings via a digital screen, 5 memory slots, and cutting speed adjustment. Optional features like a material feeder and static electricity remover are available.

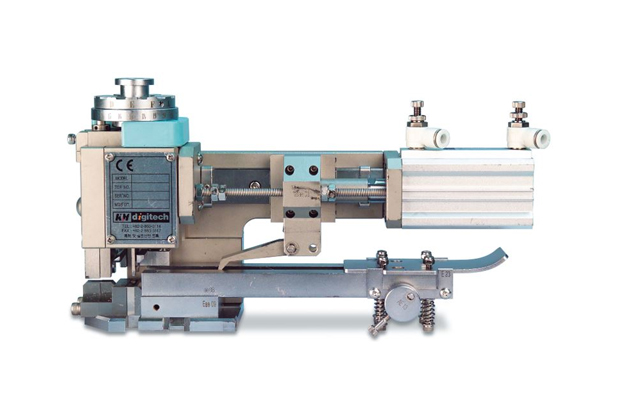

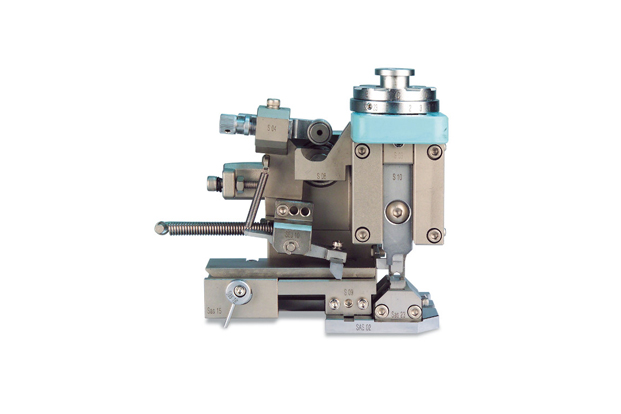

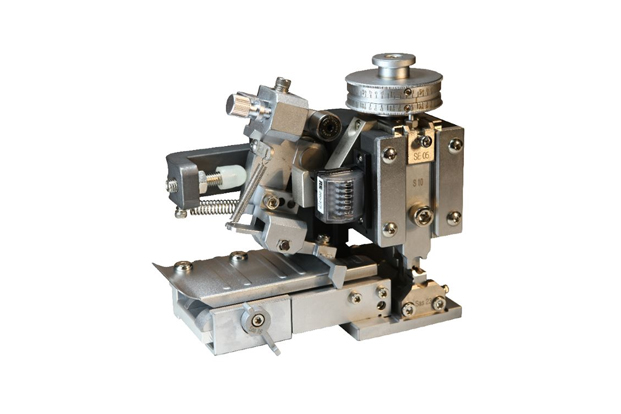

- Diverse applicator product lines (KM-901C, KM-CA+01S, KM-AA+01S, KM-903AN, KM-903A) incorporate fine adjustment of crimping height and wire feeding to minimize crimping defects. Offering various models such as CAM type and air-feeding guide adjustable types, these applicators provide optimized solutions for customer-specific working environments.Diverse applicator product lines (KM-901C, KM-CA+01S, KM-AA+01S, KM-903AN, KM-903A) incorporate fine adjustment of crimping height and wire feeding to minimize crimping defects. Offering various models such as CAM type and air-feeding guide adjustable types, these applicators provide optimized solutions for customer-specific working environments.

- Peripheral equipment like the LIMS-SU1 seal insertion unit, LIMS-Conveyor unit, and LIMS-Prefeeder and KMF-303 wire pre-feeding units integrate with automatic crimping machines to maximize efficiency and automation of the wire processing workflow. The KMF-303 wire feeder, in particular, adopts a bobbin rotation method for stable feeding of special and thin wires.Peripheral equipment like the LIMS-SU1 seal insertion unit, LIMS-Conveyor unit, and LIMS-Prefeeder and KMF-303 wire pre-feeding units integrate with automatic crimping machines to maximize efficiency and automation of the wire processing workflow. The KMF-303 wire feeder, in particular, adopts a bobbin rotation method for stable feeding of special and thin wires.

- Core Advantages

- Unrivaled technology and know-how based on over 30 years of leadership in the harness equipment market.Unrivaled technology and know-how based on over 30 years of leadership in the harness equipment market.

- Technological leadership through the development of innovative products such as the LIMS automatic crimping machine series.Technological leadership through the development of innovative products such as the LIMS automatic crimping machine series.

- Ability to provide customized solutions and reasonable pricing reflecting customer requirements.Ability to provide customized solutions and reasonable pricing reflecting customer requirements.

- Future-oriented technological development capabilities, preparing for the smart era by integrating AI technology into automation facilities.Future-oriented technological development capabilities, preparing for the smart era by integrating AI technology into automation facilities.

- A global network with 5 domestic sales offices and distributors in 8 overseas countries, ensuring prompt customer feedback.A global network with 5 domestic sales offices and distributors in 8 overseas countries, ensuring prompt customer feedback.

- Development of remote control and central computer control systems for automatic crimping machines, maximizing equipment management efficiency.Development of remote control and central computer control systems for automatic crimping machines, maximizing equipment management efficiency.

- Target Industrie

- The wiring harness sector is critical for various industries including automotive, home appliances, and electronics, where KM Digitech's equipment plays a pivotal role in the production process.The wiring harness sector is critical for various industries including automotive, home appliances, and electronics, where KM Digitech's equipment plays a pivotal role in the production process.

- Provision of automation solutions aimed at enhancing productivity and efficiency in the labor-intensive wiring harness industry.Provision of automation solutions aimed at enhancing productivity and efficiency in the labor-intensive wiring harness industry.

- Supply of essential equipment for wire processing and assembly in the electrical, electronics, and control equipment manufacturing sectors.Supply of essential equipment for wire processing and assembly in the electrical, electronics, and control equipment manufacturing sectors.

- Major Markets

- MoroccoMorocco

- Japan, China, Malaysia, IndiaJapan, China, Malaysia, India

- Belgium, Russia, Turkey, PortugalBelgium, Russia, Turkey, Portugal

- USAUSA

- Certifications/Patents

- Establishment of a robust quality management system through ISO 9001 certification (acquired in 2006, 2009, 2012).Establishment of a robust quality management system through ISO 9001 certification (acquired in 2006, 2009, 2012).

- Securing product safety for entry into the European market with CE certification (Digital wire processing machine in 1999, KM-806, KM-809D, KM-802N in 2008, KM-7000 in 2014).Securing product safety for entry into the European market with CE certification (Digital wire processing machine in 1999, KM-806, KM-809D, KM-802N in 2008, KM-7000 in 2014).

- Recognition of technological competitiveness through selection as an INNO-BIZ (Innovation Business) A-grade company (2007) and Venture Company certification (2001).Recognition of technological competitiveness through selection as an INNO-BIZ (Innovation Business) A-grade company (2007) and Venture Company certification (2001).

- Demonstrated potential for growth in overseas markets through designation as an Export Promising Small and Medium Business (2001, 2008) and awards such as the Export Million Dollar Tower (2004) and Three Million Dollar Tower (2006).Demonstrated potential for growth in overseas markets through designation as an Export Promising Small and Medium Business (2001, 2008) and awards such as the Export Million Dollar Tower (2004) and Three Million Dollar Tower (2006).

- Acknowledgement of technological development and human resource capabilities through the Presidential Award for Excellent Capital Goods Development (2001) and CEO Im Seong-ju's selection as 'Function Korea Person of the Month' (2016).Acknowledgement of technological development and human resource capabilities through the Presidential Award for Excellent Capital Goods Development (2001) and CEO Im Seong-ju's selection as 'Function Korea Person of the Month' (2016).

Introduction

Key Products

Location

39 Saneop-ro 92beon-gil, Gwonseon-gu, Suwon, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기