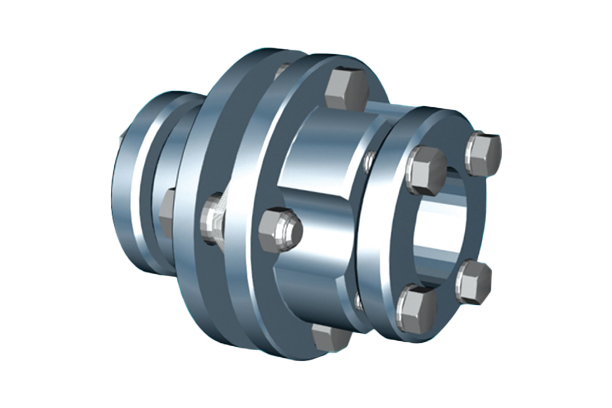

JAC COUPLING

Description

|

|

A3 (4-bolt single) type Dimensions

|

SIZE

No. |

Basic

torque (kgf.m) |

max.

radial load (kg) |

max.

rpm |

Standard(N-hub)

|

K-hub

|

GD2

(kgf.cm2) |

weight

(kg) |

|||||||

|

A

|

B

|

Emax.

|

F

|

G

|

H

|

P-hub

|

Z-hub

|

|||||||

|

F

|

H

|

Emax.

|

||||||||||||

|

05

|

3.4

|

15

|

47,000

|

67.4

|

56.9

|

22

|

25.4

|

6.1

|

33.1

|

40

|

47

|

32

|

8

|

0.6

|

|

10

|

9.2

|

25

|

39,000

|

81.1

|

57.4

|

32

|

25.4

|

6.6

|

45.8

|

40

|

58

|

40

|

24

|

1.1

|

|

15

|

18

|

56

|

34,000

|

92.8

|

65.8

|

35

|

28.7

|

8.4

|

50.8

|

45

|

66

|

42

|

48

|

1.7

|

|

20

|

25

|

83

|

30,000

|

103.7

|

78.2

|

42

|

33.5

|

11.2

|

61

|

50

|

77

|

48

|

80

|

2.4

|

|

25

|

43

|

120

|

25,000

|

125.8

|

93.9

|

50

|

41.1

|

11.7

|

71.2

|

60

|

92

|

60

|

224

|

4.3

|

|

30

|

79

|

180

|

22,000

|

143

|

107.3

|

60

|

47.8

|

11.7

|

83.9

|

70

|

104

|

70

|

440

|

6.9

|

|

35

|

130

|

270

|

19,000

|

168

|

131.2

|

72

|

57.2

|

16.8

|

105.5

|

85

|

129

|

85

|

1080

|

11.5

|

|

40

|

210

|

380

|

16,000

|

194.1

|

144.1

|

82

|

63.5

|

17

|

118.2

|

100

|

147

|

95

|

2080

|

16.4

|

|

45

|

340

|

450

|

15,000

|

214.2

|

174

|

95

|

76.2

|

21.6

|

137.2

|

115

|

166

|

110

|

3520

|

28

|

|

50

|

500

|

610

|

13,000

|

246.2

|

201.7

|

108

|

88.9

|

23.9

|

156.3

|

135

|

191

|

120

|

7200

|

37

|

|

55

|

650

|

650

|

11,000

|

275.6

|

230.4

|

118

|

101.6

|

27.2

|

169

|

150

|

209

|

130

|

12800

|

51

|

|

(Note) Coupling weight and GD2,without Bore machining

|

||||||||||||||

A4 , AX (4-bolt double) type Dimensions

|

SIZE

No. |

Basic

torque (kgf.m) |

A

|

B

|

Emax.

|

F

|

G

|

H

|

A4-type

|

AX-type

|

||||

|

D

|

weight

(kg) |

GD2

(kg.cm2) |

D

|

weight

(kg) |

GD2

(kgf.cm2) |

||||||||

|

05

|

3.4

|

67.4

|

2F+D

|

22

|

25.4

|

6.1

|

33.1

|

88.9

|

1.2

|

18

|

36

|

1.1

|

17.8

|

|

10

|

9.2

|

81.1

|

32

|

25.4

|

6.6

|

45.8

|

88.9

|

1.9

|

44

|

39

|

1.7

|

41

|

|

|

15

|

18

|

92.8

|

35

|

28.7

|

8.4

|

50.8

|

101.6

|

2.9

|

84

|

47

|

2.7

|

79

|

|

|

20

|

25

|

103.7

|

42

|

33.5

|

11.2

|

61

|

127

|

7.1

|

396

|

53

|

6.6

|

136

|

|

|

25

|

43

|

125.8

|

50

|

41.1

|

11.7

|

71.2

|

127

|

7.1

|

386

|

62

|

6.6

|

337

|

|

|

30

|

79

|

143

|

60

|

47.8

|

11.7

|

83.9

|

127

|

10.8

|

386

|

69

|

6.6

|

775

|

|

|

35

|

130

|

168

|

72

|

57.2

|

16.8

|

105.5

|

127

|

16.3

|

1680

|

78

|

15.6

|

1628

|

|

|

40

|

210

|

194.1

|

82

|

63.5

|

17

|

118.2

|

139.7

|

24.7

|

3400

|

89

|

24

|

3317

|

|

|

45

|

340

|

214.2

|

95

|

76.2

|

21.6

|

137.2

|

152.4

|

32.5

|

5600

|

97

|

31.5

|

5428

|

|

|

50

|

500

|

246.2

|

108

|

88.9

|

23.9

|

156.3

|

177.8

|

50

|

11200

|

109

|

48.4

|

10865

|

|

|

55

|

650

|

275.6

|

118

|

101.6

|

27.2

|

169

|

177.8

|

75

|

20400

|

134

|

73.9

|

20127

|

|

|

(Note) Coupling weight and GD2,without Bore machining

|

|||||||||||||

E4 (6-bolt double) type Dimensions

|

SIZE

No. |

Basic

torque (kgf.m) |

A

(mm) |

B

(mm) |

C

(mm) |

D

(mm) |

Emax.

(mm) |

F

(mm) |

G

(mm) |

H

(mm) |

allow-

able End Float (±mm) |

GD2

(kgf.m2) |

weight

(kg) |

|

00

|

58

|

119

|

168

|

39.4

|

60

|

51

|

54

|

10.3

|

74

|

3

|

0.03

|

6

|

|

01

|

94

|

137

|

198

|

50

|

72

|

55

|

63

|

11

|

81

|

3.4

|

0.06

|

9.1

|

|

02

|

174

|

161

|

238

|

67.2

|

90

|

67

|

74

|

11.4

|

97

|

3.6

|

0.14

|

16.9

|

|

03

|

341

|

180

|

269

|

82.4

|

109

|

72

|

80

|

13.3

|

104

|

4.2

|

0.26

|

21.6

|

|

04

|

500

|

212

|

308

|

87.6

|

118

|

85

|

95

|

15.2

|

124

|

4.5

|

0.59

|

35.1

|

|

05

|

620

|

276

|

377

|

118

|

153

|

111

|

112

|

17.5

|

161

|

3.9

|

1.8

|

65.1

|

|

10

|

840

|

276

|

377

|

115

|

153

|

111

|

112

|

19

|

161

|

3.9

|

1.9

|

66.1

|

|

15

|

1090

|

308

|

440

|

134

|

172

|

133

|

134

|

19

|

193

|

4.2

|

3.7

|

107.8

|

|

20

|

1820

|

346

|

497

|

148

|

191

|

152

|

153

|

21.5

|

218

|

4.9

|

6.7

|

156.1

|

|

25

|

2690

|

375

|

553

|

175

|

223

|

165

|

165

|

24

|

240

|

5.2

|

10.6

|

211.8

|

|

30

|

3410

|

410

|

610

|

195

|

254

|

178

|

178

|

29.5

|

258

|

5.4

|

16.5

|

274.5

|

|

35

|

4070

|

445

|

646

|

211

|

270

|

187

|

188

|

29.5

|

272

|

5.6

|

23.9

|

333.3

|

|

40

|

4720

|

470

|

686

|

212

|

274

|

205

|

206

|

31

|

297

|

6.3

|

30.7

|

399.2

|

|

45

|

6100

|

511

|

749

|

223

|

287

|

231

|

231

|

32

|

334

|

6.7

|

48

|

525.3

|

|

50

|

7620

|

556

|

800

|

227

|

292

|

254

|

254

|

32.5

|

364

|

7.3

|

72.9

|

676.3

|

|

(Note) Coupling weight and GD2,without Bore machining

|

||||||||||||

G4 (8-bolt double) type Dimensions

|

SIZE

No. |

Basic

torque (kgf.m) |

A

(mm) |

B

(mm) |

C

(mm) |

D

(mm) |

Emax.

(mm) |

F

(mm) |

G

(mm) |

H

(mm) |

allow-

able End Float (±mm) |

GD2

(kgf.m2) |

weight

(kg) |

|

01

|

392

|

214

|

333

|

92.6

|

117

|

95

|

108

|

12.2

|

137

|

2.1

|

0.65

|

38

|

|

03

|

726

|

246

|

369

|

99.6

|

127

|

108

|

121

|

13.7

|

156

|

2.1

|

1.24

|

55.5

|

|

05

|

915

|

276

|

421

|

118

|

153

|

111

|

134

|

17.5

|

161

|

2.1

|

1.8

|

72.2

|

|

10

|

1100

|

276

|

421

|

115

|

153

|

111

|

134

|

19

|

161

|

2.1

|

1.8

|

73.3

|

|

15

|

1570

|

308

|

492

|

134

|

172

|

133

|

160

|

19

|

193

|

2.4

|

3.7

|

119.7

|

|

20

|

2610

|

346

|

557

|

146

|

191

|

152

|

183

|

22.5

|

218

|

2.9

|

6.8

|

174.3

|

|

25

|

3850

|

375

|

619

|

167

|

223

|

165

|

198

|

28

|

240

|

3.1

|

10.8

|

233.8

|

|

30

|

4810

|

410

|

682

|

192

|

254

|

178

|

214

|

31

|

258

|

3.3

|

16.7

|

305.3

|

|

35

|

5820

|

445

|

720

|

208

|

270

|

187

|

225

|

31

|

272

|

3.6

|

25

|

367.4

|

|

40

|

6570

|

470

|

768

|

206

|

274

|

205

|

247

|

34

|

297

|

4

|

31.1

|

447.5

|

|

45

|

8530

|

511

|

843

|

221

|

287

|

231

|

278

|

35

|

334

|

4.5

|

48

|

591.6

|

|

50

|

10530

|

556

|

902

|

218

|

292

|

254

|

305

|

37

|

365

|

5

|

74.7

|

761.4

|

|

(Note) Coupling weight and GD2,without Bore machining

|

||||||||||||