Overview

- Summary

- A specialized manufacturer of power transmission couplings, producing a diverse range of products including gear, disc, grid, rubber, tire, jaw, muff, wire drum, brake drum, wind turbine, and composite couplings for various industrial applications worldwideA specialized manufacturer of power transmission couplings, producing a diverse range of products including gear, disc, grid, rubber, tire, jaw, muff, wire drum, brake drum, wind turbine, and composite couplings for various industrial applications worldwide

- Key Products/Technologies

- Gear Coupling: Conforming to KS and other standards, engineered for high performance with years of technical experience and field experiments, featuring heavy load handling capacity and minimal noise and vibration during high-speed operation.Gear Coupling: Conforming to KS and other standards, engineered for high performance with years of technical experience and field experiments, featuring heavy load handling capacity and minimal noise and vibration during high-speed operation.

- Disc Coupling: Requiring no lubrication due to the absence of sliding, frictional, or moving parts, offering low friction, noise, and energy loss, with high torsional stiffness and no backlash, ideal for machine tools, indexing systems, and printing machines demanding precise shaft rotation and phase control.Disc Coupling: Requiring no lubrication due to the absence of sliding, frictional, or moving parts, offering low friction, noise, and energy loss, with high torsional stiffness and no backlash, ideal for machine tools, indexing systems, and printing machines demanding precise shaft rotation and phase control.

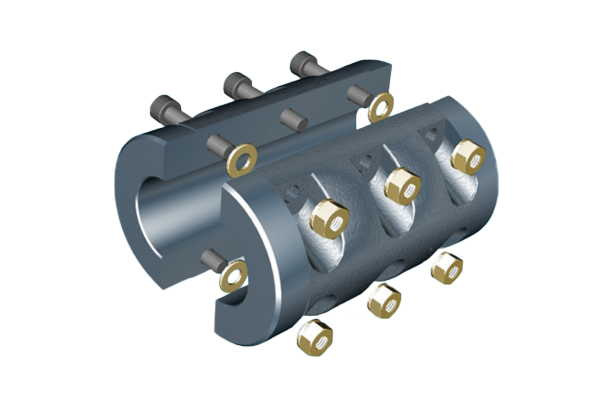

- Grid Coupling: Providing favorable convenience and cost reduction by absorbing shock and vibration loads through the flexibility of the grid, ensuring easy installation and replacement.Grid Coupling: Providing favorable convenience and cost reduction by absorbing shock and vibration loads through the flexibility of the grid, ensuring easy installation and replacement.

- Rubber Coupling: Facilitating easy installation and fit by eliminating most vibration and noise, thereby improving working conditions and extending machine service life, requiring no lubrication even under severe conditions, and simplifying designs where shaft vibration is a concern.Rubber Coupling: Facilitating easy installation and fit by eliminating most vibration and noise, thereby improving working conditions and extending machine service life, requiring no lubrication even under severe conditions, and simplifying designs where shaft vibration is a concern.

- Tire Coupling: Utilizing natural compounds for suitability in most conditions, capable of handling combinations of parallel, angular, and axial displacements, reducing torsional vibrations, and absorbing shock loads without the need for lubrication or special tools.Tire Coupling: Utilizing natural compounds for suitability in most conditions, capable of handling combinations of parallel, angular, and axial displacements, reducing torsional vibrations, and absorbing shock loads without the need for lubrication or special tools.

- Jaw Coupling: Torsionally flexible and designed for positive torque transmission, puncture-proof, efficiently attenuating and reducing operational vibrations and shocks, with easy setting and repairing.Jaw Coupling: Torsionally flexible and designed for positive torque transmission, puncture-proof, efficiently attenuating and reducing operational vibrations and shocks, with easy setting and repairing.

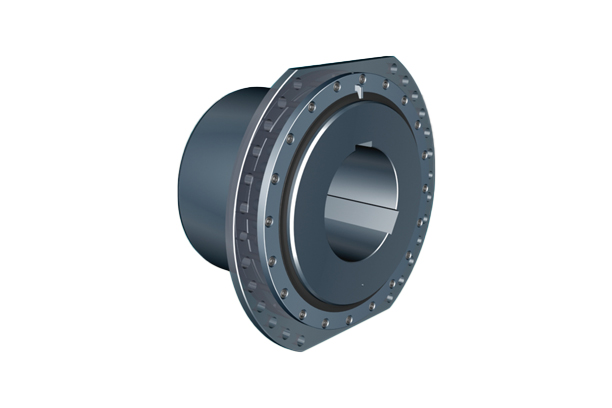

- Wire Drum Coupling: Designed for installation in drum drives of cranes and conveying systems, suitable for harsh and demanding operating conditions in steel works and continuous heavy-load operations in shore cranes.Wire Drum Coupling: Designed for installation in drum drives of cranes and conveying systems, suitable for harsh and demanding operating conditions in steel works and continuous heavy-load operations in shore cranes.

- Wind Turbine Coupling: Engineered for wind turbine installations to transmit power from the gearbox to the generator, correcting shaft misalignment, and incorporating a torque limiter for overload prevention.Wind Turbine Coupling: Engineered for wind turbine installations to transmit power from the gearbox to the generator, correcting shaft misalignment, and incorporating a torque limiter for overload prevention.

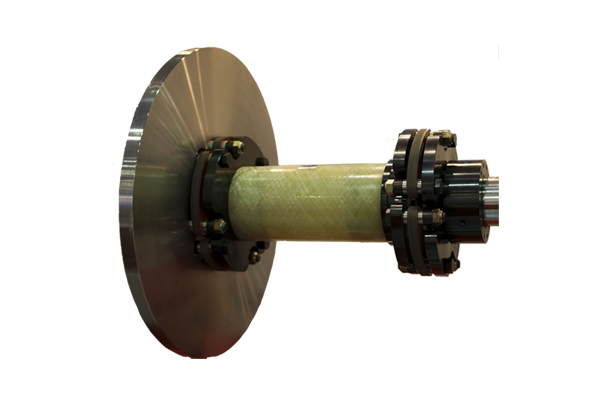

- Composite Coupling: Designed for cooling tower installations, resistant to rust, lightweight for easy installation and replacement, offering compensation for large misalignments, long fatigue life, and high flexibility.Composite Coupling: Designed for cooling tower installations, resistant to rust, lightweight for easy installation and replacement, offering compensation for large misalignments, long fatigue life, and high flexibility.

- Core Advantages

- Over 20 years of specialized expertise and accumulated know-how in manufacturing power transmission couplings.Over 20 years of specialized expertise and accumulated know-how in manufacturing power transmission couplings.

- High-precision machinery facilities and stable quality control ensuring the supply of superior performance couplings, with manufacturing capabilities for high-quality standard couplings conforming to KS and JIS requirements.High-precision machinery facilities and stable quality control ensuring the supply of superior performance couplings, with manufacturing capabilities for high-quality standard couplings conforming to KS and JIS requirements.

- A diverse portfolio of coupling models including gear, disc, grid, rubber, tire, jaw, wire drum, wind turbine, and composite, providing optimized solutions for various customer needs and industrial applications.A diverse portfolio of coupling models including gear, disc, grid, rubber, tire, jaw, wire drum, wind turbine, and composite, providing optimized solutions for various customer needs and industrial applications.

- Specialized technical strengths in heavy load handling, vibration and noise reduction, shock absorption, and shaft misalignment correction, contributing to extended machine lifespan and improved working conditions.Specialized technical strengths in heavy load handling, vibration and noise reduction, shock absorption, and shaft misalignment correction, contributing to extended machine lifespan and improved working conditions.

- Active export to major industrial countries including Japan, China, Southeast Asia, North America, Europe, and South America, establishing a strong competitive presence in global markets.Active export to major industrial countries including Japan, China, Southeast Asia, North America, Europe, and South America, establishing a strong competitive presence in global markets.

- Collaborative relationships and joint technology development with major domestic corporations such as Doosan Heavy Industries, Hyundai Steel, and POSCO, enhancing technological capabilities and building trust.Collaborative relationships and joint technology development with major domestic corporations such as Doosan Heavy Industries, Hyundai Steel, and POSCO, enhancing technological capabilities and building trust.

- Continuous investment in R&D and new technology development, including specialized couplings for wind turbines and expansion into EV components, securing future growth engines.Continuous investment in R&D and new technology development, including specialized couplings for wind turbines and expansion into EV components, securing future growth engines.

- Target Industrie

- Mechanical Engineering: Power transmission devices for general industrial machinery and equipment.Mechanical Engineering: Power transmission devices for general industrial machinery and equipment.

- Steel Industry: Steel mills and processing facilities, including POSCO and Hyundai Steel.Steel Industry: Steel mills and processing facilities, including POSCO and Hyundai Steel.

- Cranes and Hoisting Equipment: Wire drum couplings for crane and hoist drum drive systems.Cranes and Hoisting Equipment: Wire drum couplings for crane and hoist drum drive systems.

- Wind Power Generation: Wind turbine couplings for connecting gearboxes to generators in wind power plants.Wind Power Generation: Wind turbine couplings for connecting gearboxes to generators in wind power plants.

- Cooling Towers: Composite couplings for cooling tower installations.Cooling Towers: Composite couplings for cooling tower installations.

- Precision Equipment and Printing Machines: Disc couplings for equipment requiring precise shaft rotation and phase control.Precision Equipment and Printing Machines: Disc couplings for equipment requiring precise shaft rotation and phase control.

- Heavy Machinery and Mining: Power transmission systems in heavy machinery and mining sectors.Heavy Machinery and Mining: Power transmission systems in heavy machinery and mining sectors.

- Paper and Sugar Mills: Machinery and equipment in paper and sugar manufacturing plants.Paper and Sugar Mills: Machinery and equipment in paper and sugar manufacturing plants.

- Cement Plants: Power transmission devices in cement factories.Cement Plants: Power transmission devices in cement factories.

- Shipbuilding: Power transmission components in marine vessels.Shipbuilding: Power transmission components in marine vessels.

- Automotive and Agricultural Machinery: Initial business areas focusing on automotive and agricultural machinery parts.Automotive and Agricultural Machinery: Initial business areas focusing on automotive and agricultural machinery parts.

- Electric Vehicle Components: High-performance coupling solutions for EV electric motors and drive units.Electric Vehicle Components: High-performance coupling solutions for EV electric motors and drive units.

- Major Markets

- Egypt, NigeriaEgypt, Nigeria

- Japan, China, Thailand, Singapore, Malaysia, Indonesia, Taiwan, Hong Kong, Saudi Arabia, Vietnam, IndiaJapan, China, Thailand, Singapore, Malaysia, Indonesia, Taiwan, Hong Kong, Saudi Arabia, Vietnam, India

- EU, Germany, France, Italy, Finland, Bulgaria, Belarus, Estonia, AlbaniaEU, Germany, France, Italy, Finland, Bulgaria, Belarus, Estonia, Albania

- United States, MexicoUnited States, Mexico

- AustraliaAustralia

- Brazil, Ecuador, ParaguayBrazil, Ecuador, Paraguay

- Certifications/Patents

- ISO 9001 Certification (2001)ISO 9001 Certification (2001)

- QS 9000 Certification (2001)QS 9000 Certification (2001)

- Reliability Certification for Parts and Materials (2006, Ministry of Commerce, Industry and Energy, German TUV, French BV)Reliability Certification for Parts and Materials (2006, Ministry of Commerce, Industry and Energy, German TUV, French BV)

- INNO-BIZ Certification (2009)INNO-BIZ Certification (2009)

- Venture Company Certification (2011, Korea Technology Finance Corporation)Venture Company Certification (2011, Korea Technology Finance Corporation)

- API Spec Q1 Certification (2016, American Petroleum Institute)API Spec Q1 Certification (2016, American Petroleum Institute)

- Manufacturing Technology for 750KW Wind Turbine Powertrain High-Speed Coupling (2014, Minister of Trade, Industry and Energy)Manufacturing Technology for 750KW Wind Turbine Powertrain High-Speed Coupling (2014, Minister of Trade, Industry and Energy)

- Selection as a Leading Company for 3MW Offshore Wind Turbine Coupling Development (2012, Ministry of Knowledge Economy)Selection as a Leading Company for 3MW Offshore Wind Turbine Coupling Development (2012, Ministry of Knowledge Economy)

- Establishment of a Corporate R&D Center (2009) for continuous development of new technologies and products.Establishment of a Corporate R&D Center (2009) for continuous development of new technologies and products.

Introduction

Key Products

Location

69 Saebyeok-ro, Sasang-gu, Busan, South Korea

클릭하여 위치 살펴보기