This product is manufactured by

HAN KIL PRECISION

Manufacturer information

HAN KIL PRECISION

Painting equipment and facilities

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

HAN KIL PRECISION

Product Type

Machine

Brand

-

SKU

122828

Product Name

Coating Thickness Measurement

Model Name

100LT, 700BAR

Size

-

Weight

-

Product Details

More products

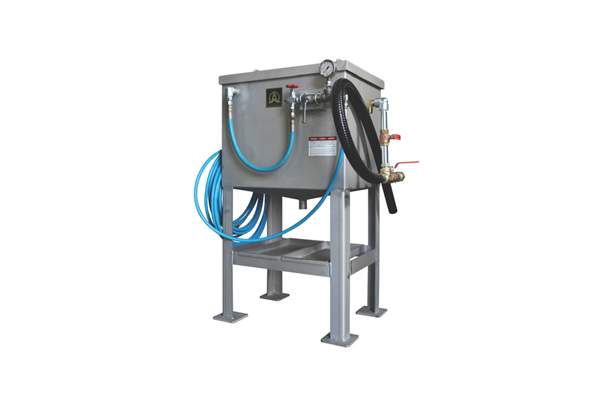

Airless Pump Tester100LT, 700BAR

Airless Pump 33:1HK-331

Airless Pump 73:1HK-731

Auto GunHKBP-100

Airless Pump 67:1HK-671

Airless Pump 54:1HK-541

Hydraulic PumpHK-HP-1000

Check Mate PumpHK-CM-800

Airless Pump 42:1HK-421

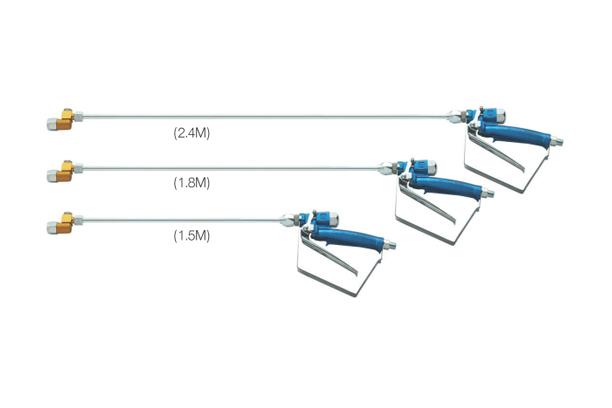

Pole GunHKPG-800

Touch Up GunHKTG-500

Airless Pump 72:1HK-721

High-performance Dual Component Airless Paint Spraying EquipmentHK-PFP-2000

Airless Spray GunHK-747 OMEGA

Overhead Spray MachineHK-BP-3000

1/4