This product is manufactured by

ECM TECHNOLOGIES

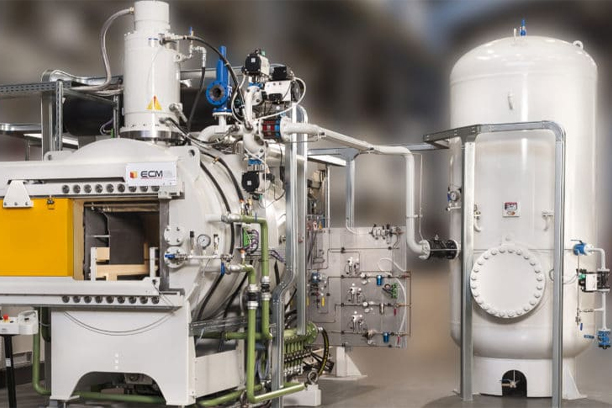

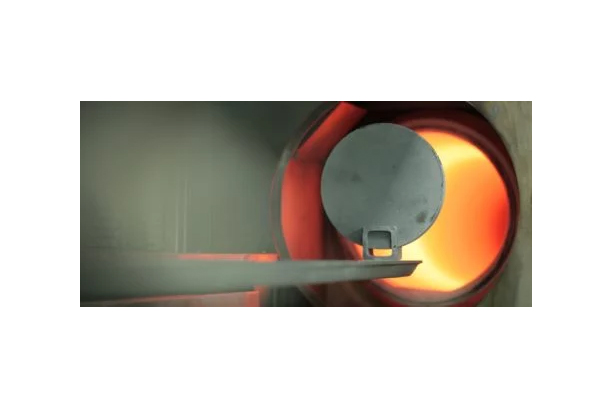

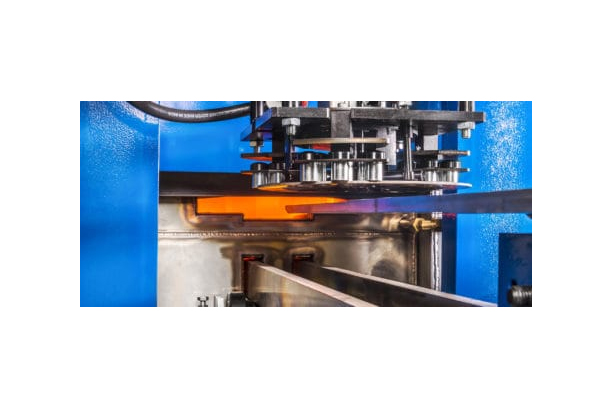

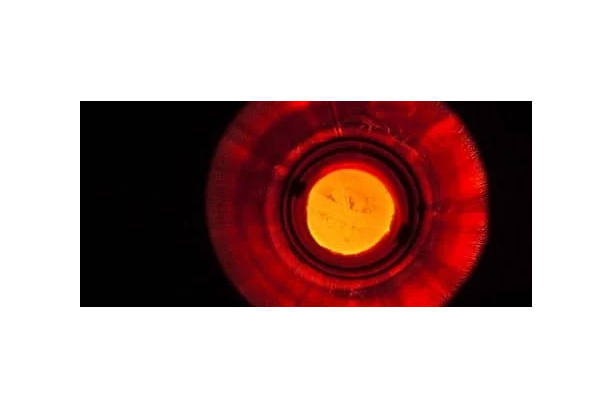

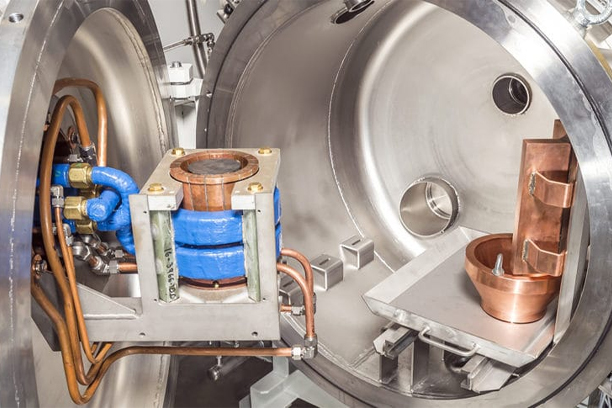

VIM FURNACE

Model Name

-

Manufacturer information

ECM TECHNOLOGIES

Verified & Trusted Manufacturer

Industrial furnace manufacturer, ICBP, Carburizing furnaces, Vacuum furnaces, Induction furnaces and melting

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

ECM TECHNOLOGIES

Product Type

Machine

Brand

-

SKU

131176

Product Name

VIM FURNACE

Model Name

-

Size

-

Weight

-

Product Details

More products

VACUUM FURNACES (RUBIS)RUBIS 18-20, RUBIS 30-50, RUBIS 40-60, RUBIS 50-80, RUBIS 110-200

CARBURIZING FURNACES (PFTH)PFTH 900, PFTH 1500

CARBURIZING FURNACES (ICBP® DUO)ICBP DUO 644, ICBP DUO 966, ICBP DUO 1299

CARBURIZING FURNACES (ICBP® MONO)ICBP MONO 966, ICBP MONO 1299

SEMCO

TAILOR MADE FURNACESSOUS-TITRE

NUCLEAR APPLICATIONS

SERTHEL

CYBERSTAR

SEMCO

ECM GREENTECH

VACUUM FURNACES (TUBESTAR)TUBESTAR

CARBURIZING FURNACES (ICBP® FLEX)ICBP® FLEX

CCIM FURNACE

LABORATORY FURNACE FOR MELTING

BATCH TYPE RTP FURNACERTP JetLight Series

1/4