This product is manufactured by

DUCLEAN

Manufacturer information

DUCLEAN

Dust collector manufacturer, Environmental equipment, Air pollution prevention facility and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

DUCLEAN

Product Type

Machine

Brand

-

SKU

133969

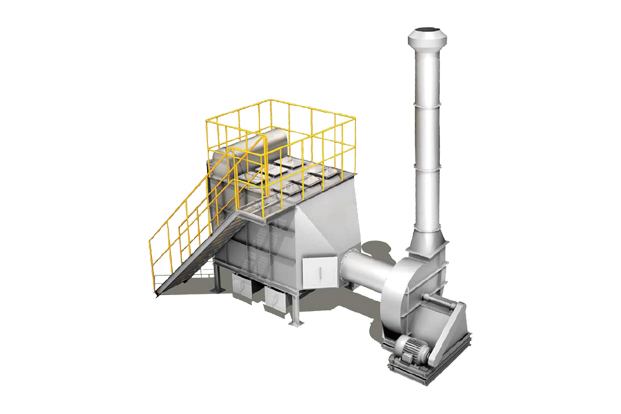

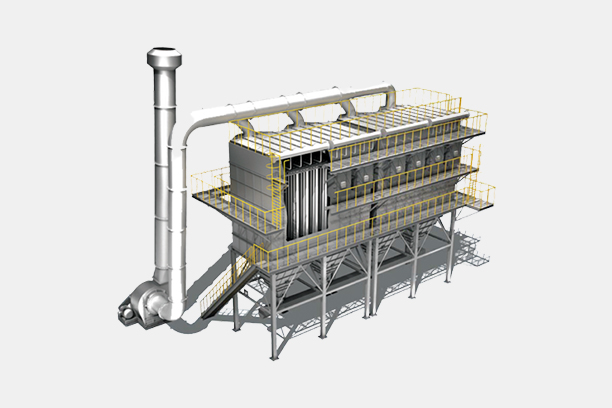

Product Name

Absorption Tower

Model Name

-

Size

-

Weight

-

Product Details

More products

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65974_eoehov.jpg)

[Discontinued] Industrial Vacuum CleanerCH-2500BH

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65968_ojhqcr.jpg)

[Discontinued] Industrial Vacuum CleanerCH-3500SW

![[Discontinued] Business Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65952_xthppb.jpg)

[Discontinued] Business Vacuum CleanerCH-107S

Bag Filter Type Vacuum Dust Collector (MSR Series)MSR-229, MSR-329, MSR-339, MSR-429, MSR-529, MSR-629, MSR-639

Cleaner Attached Dust Collector (APV/MSV Series)AP-100, AP-200, AP-200/629, AP-300, AP-500, AP-750, AP-829, AP-1000, AP-1500, AP-2000, AP-3000, MS-50, MS-100, MS-200, MS-300, MS-500, MS-750, MS-1000, MS-1500

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65977_cpmrjt.jpg)

[Discontinued] Industrial Vacuum Cleaner2Tank-2500SN

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65976_faibeh.jpg)

[Discontinued] Industrial Vacuum Cleaner2Tank-2700

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65973_htavtq.jpg)

[Discontinued] Industrial Vacuum CleanerCH-3500N

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65971_wwykuu.jpg)

[Discontinued] Industrial Vacuum CleanerCH-1500N

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65970_qxdqpc.jpg)

[Discontinued] Industrial Vacuum CleanerCH-345SW

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65969_wscrnm.jpg)

[Discontinued] Industrial Vacuum CleanerCH-330SW

![[Discontinued] Industrial Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65963_uofnio.jpg)

[Discontinued] Industrial Vacuum CleanerCH-220F

![[Discontinued] Business Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65962_vlbogd.jpg)

[Discontinued] Business Vacuum CleanerCH-150T

![[Discontinued] Business Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65959_cxxqkf.jpg)

[Discontinued] Business Vacuum CleanerCH-115S

![[Discontinued] Business Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65958_gesneu.jpg)

[Discontinued] Business Vacuum CleanerCH-120P

![[Discontinued] Business Vacuum Cleaner](https://cdn.komachine.com/media/product/duclean_65957_egxbli.jpg)

[Discontinued] Business Vacuum CleanerCH-112SW

1/4