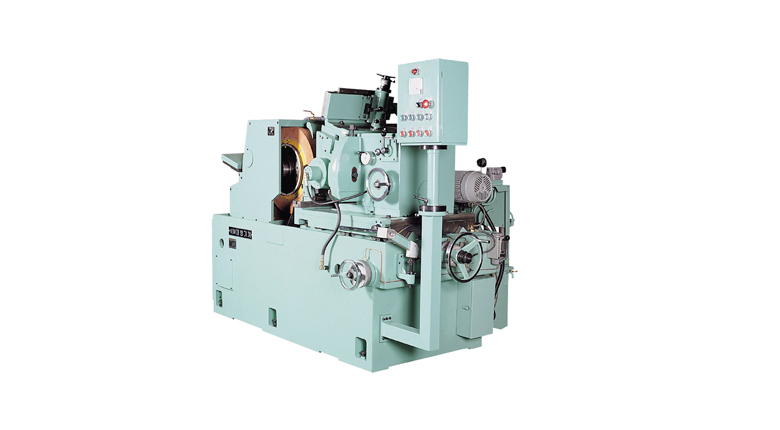

CENTERLESS GRINDING MACHINE

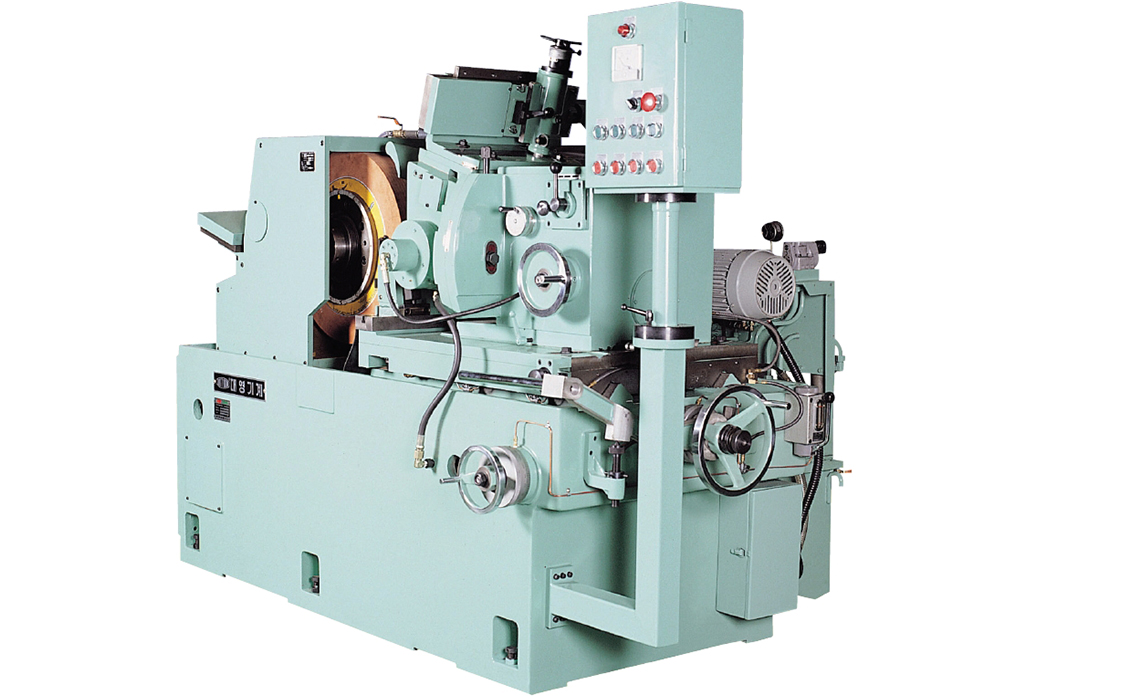

Spindle and Bearing

- Raises axial stiffness by supporting the grinding wheel with workhead and 3 bearings at shaft ends.

- Use of a hydraulic dynamic bearing to enhance high bearing stiffness and vibration reduction effect, showing excellence in powerful grinding and precision grinding.

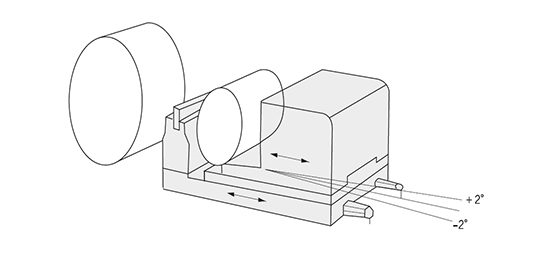

Feeding device and horizontal spin device

- Lower feeding device and upper feeding device performing respectively the feeding of the grinding stand and regulating wheel.

- Precise feed adjustment is enabled by cross feed of a feeding device, a minute feeding handle and the back flash adjustment device of a feeding screw.

- The lower slide sideway maintains long-term precision by being precisely produced by multiple profiles.

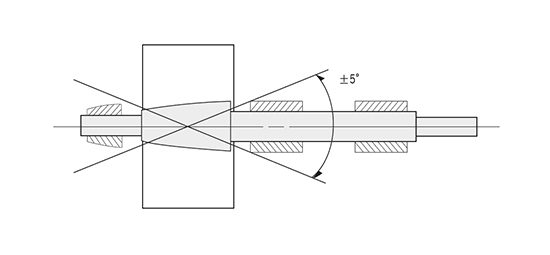

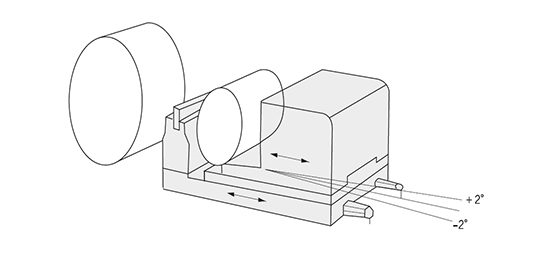

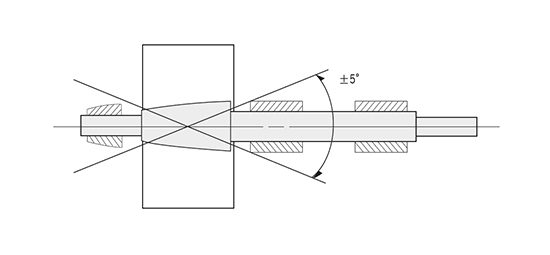

- A regulating wheel spin device capable of rotating up to ±5 degrees horizontally is used to adjust a level of parallel on the regulating wheel axis and the taper angle (adjustment during the operation also possible)

Inversion device of a regulating wheel

- Enables the regulating wheel to rotate up to ±5 degrees, which broadens ranges of the speed at which work pieces pass.

- Very useful for setting the reference position when working during the stoppage.

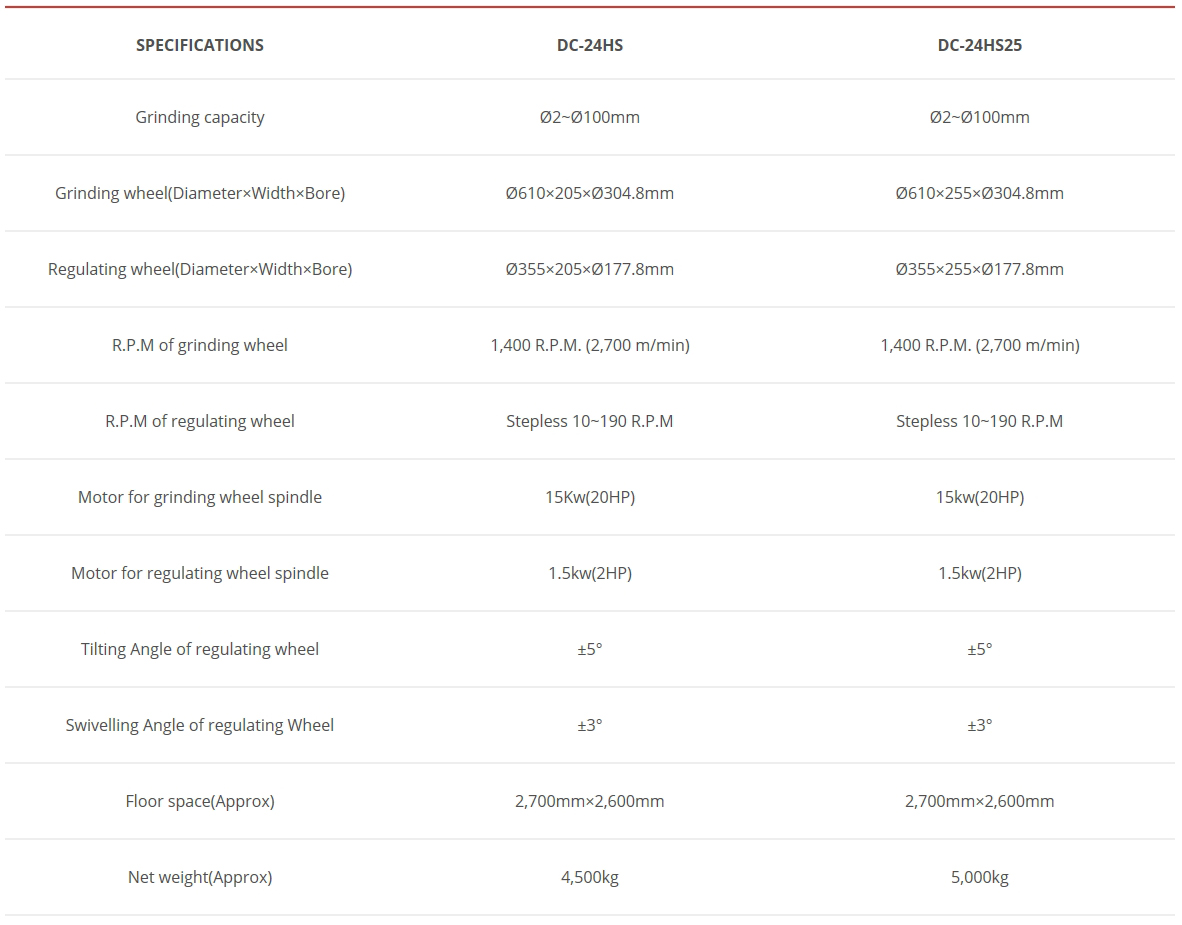

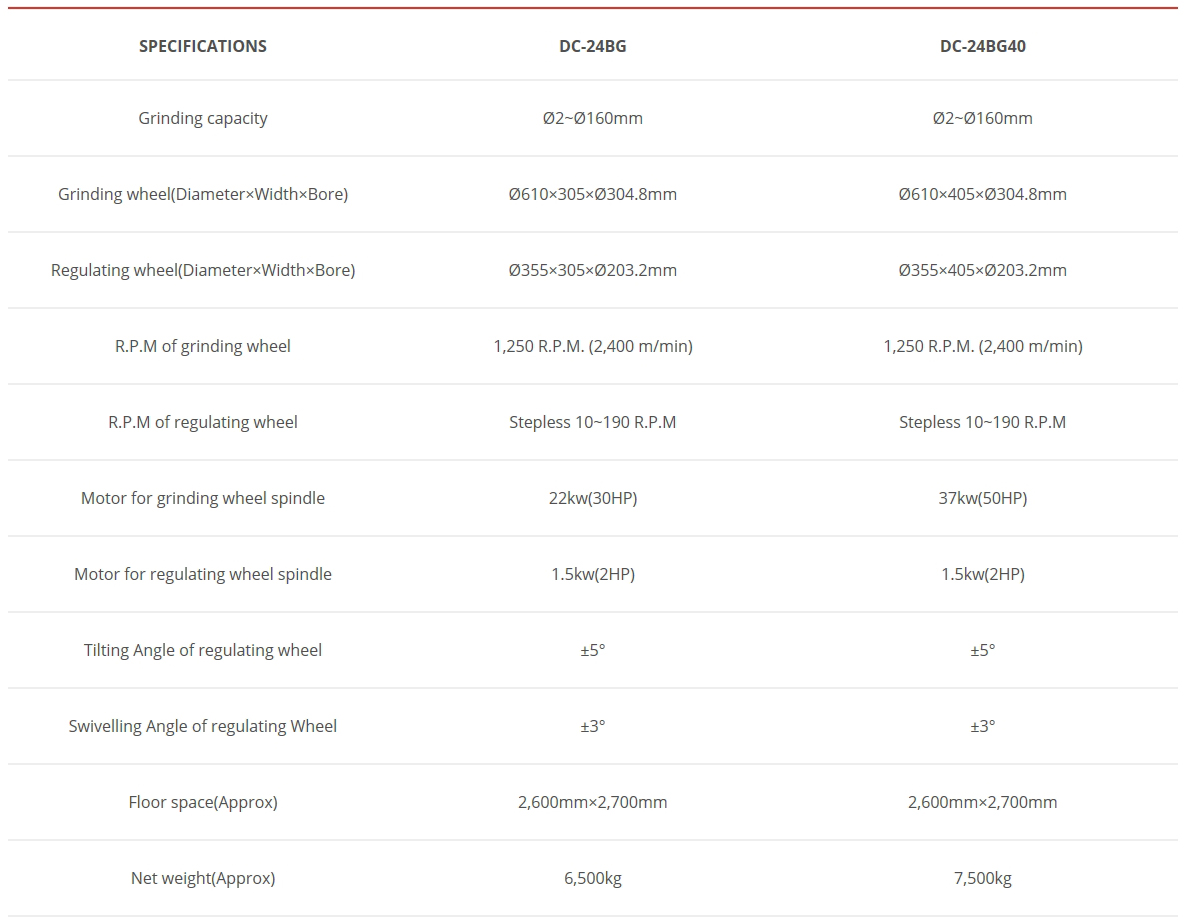

Items | Specifications |

Grinding capacity (Special) | Ø1mm~Ø40mm(Ø25mm~Ø100mm) |

Grinding wheel(Diameter×Width×Bore) | Ø455×205×Ø228.6mm |

Regulating wheek(Diameter×Width×Bore) | Ø255×205×Ø111.2mm |

R.P.M of grinding wheel | 1,500 R.P.M. (2,000 m/min) |

R.P.M of regulating wheel | 10~308 R.P.M. (Stepless) |

Motor for grinding wheel spindle | Standard 11kw(15HP)×4P |

Motor for regulating wheel spindle | 1.5kw(2HP)×4P |

Tilting angle of regulanting wheel | ±5° |

Swivelling angle of regulanting wheel | ±2° |

Floor space | 2,300mm×2,200mm |

Net weight | 3,000kg |