Overview

- Summary

- BLUE CORD Co., Ltd. is Korea's first research-oriented, technology-intensive small and medium-sized enterprise established with the goal of localizing semiconductor equipment and commercializing new technologies. The company's main business areas include the manufacturing and sales of central monitoring systems, semiconductor process equipment, and multimedia devices. It holds a strong position in the domestic semiconductor equipment industry, particularly in the development of advanced equipment such as cleanroom monitoring and control systems, Wafer Sorters, and Wafer Aligners. The company aims to grow into a world-class high-tech enterprise through continuous improvement in research productivity and future-oriented management.BLUE CORD Co., Ltd. is Korea's first research-oriented, technology-intensive small and medium-sized enterprise established with the goal of localizing semiconductor equipment and commercializing new technologies. The company's main business areas include the manufacturing and sales of central monitoring systems, semiconductor process equipment, and multimedia devices. It holds a strong position in the domestic semiconductor equipment industry, particularly in the development of advanced equipment such as cleanroom monitoring and control systems, Wafer Sorters, and Wafer Aligners. The company aims to grow into a world-class high-tech enterprise through continuous improvement in research productivity and future-oriented management.

- Key Products/Technologies

- Semiconductor Equipment: The Wafer Sorter 200/300 is an equipment designed for 200mm semiconductor processes, capable of aligning and ID reading wafers, followed by sorting them according to specific recipes. This system adheres to Semi Standard Compliance and features 2 to 4 load ports, along with a wafer transfer robot utilizing vacuum or edge grip hands. Its integrated design includes Bluecord's proprietary Wafer Pre-Aligner and FFU, ensuring efficient process management, and supports OHT and AGV integration for seamless automated logistics. The equipment offers user convenience through a color touchscreen interface and system interoperability via SECS I/II/GEM communication protocols, representing an advanced solution. The company also builds a diverse lineup of semiconductor process equipment, including Wafer Stocker, EFEM, AVIS (Visual Inspection System), Reticle/Mask Stocker, Wafer Pre-Aligner, and Edge Grip Aligner.Semiconductor Equipment: The Wafer Sorter 200/300 is an equipment designed for 200mm semiconductor processes, capable of aligning and ID reading wafers, followed by sorting them according to specific recipes. This system adheres to Semi Standard Compliance and features 2 to 4 load ports, along with a wafer transfer robot utilizing vacuum or edge grip hands. Its integrated design includes Bluecord's proprietary Wafer Pre-Aligner and FFU, ensuring efficient process management, and supports OHT and AGV integration for seamless automated logistics. The equipment offers user convenience through a color touchscreen interface and system interoperability via SECS I/II/GEM communication protocols, representing an advanced solution. The company also builds a diverse lineup of semiconductor process equipment, including Wafer Stocker, EFEM, AVIS (Visual Inspection System), Reticle/Mask Stocker, Wafer Pre-Aligner, and Edge Grip Aligner.

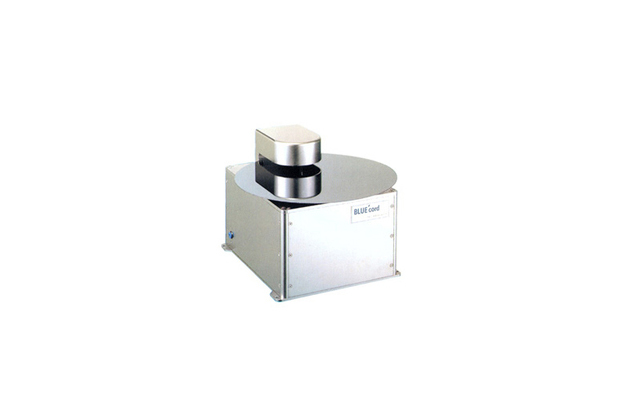

- Automatic Control Devices: Among the FFU controller SFC series, the SFC 202E-3S model is a product equipped with single-phase 220V/60Hz power specifications and single-phase AC 3-STEP motor control functions. It features a built-in EOCR function for overcurrent, phase loss, and restraint detection, ensuring stable operation through RS485 communication and motor overheat detection. The system supports flexible control with intuitive local step control and display functions, alongside remote control capabilities via a monitoring system. Capable of controlling two motors with one controller (1:2 control method), it offers customized solutions for various installation environments, either FFU-attached or duct-insertable types. The PWM series (PWM110F) is an FFU-mounted device characterized by single-phase AC208~230V, 50/60Hz, 30W power, PWM control, and RS485 communication. The MCUL series (MCUL) is an automatic control solution with single-phase AC220V, 50/60Hz, linear airflow variable control, and RS485 communication functions. The company provides a portfolio of various automatic control device models, including the LIU series (LIU214XM, LIU216XXXOY, LIU217, LIU217SPG) and LCU series (LCU301, LCU304).Automatic Control Devices: Among the FFU controller SFC series, the SFC 202E-3S model is a product equipped with single-phase 220V/60Hz power specifications and single-phase AC 3-STEP motor control functions. It features a built-in EOCR function for overcurrent, phase loss, and restraint detection, ensuring stable operation through RS485 communication and motor overheat detection. The system supports flexible control with intuitive local step control and display functions, alongside remote control capabilities via a monitoring system. Capable of controlling two motors with one controller (1:2 control method), it offers customized solutions for various installation environments, either FFU-attached or duct-insertable types. The PWM series (PWM110F) is an FFU-mounted device characterized by single-phase AC208~230V, 50/60Hz, 30W power, PWM control, and RS485 communication. The MCUL series (MCUL) is an automatic control solution with single-phase AC220V, 50/60Hz, linear airflow variable control, and RS485 communication functions. The company provides a portfolio of various automatic control device models, including the LIU series (LIU214XM, LIU216XXXOY, LIU217, LIU217SPG) and LCU series (LCU301, LCU304).

- Cleanroom Monitoring and Control System: This system is designed for local and remote monitoring and control of FFU (Fan Filter Unit) equipment to maintain the cleanliness of semiconductor cleanrooms. It enables quick and accurate monitoring of FFU operating status through wired communication, providing immediate alerts and corrective action capabilities to operators upon alarm generation. The system contributes to efficiently maintaining the clean state of large cleanroom areas with minimal personnel.Cleanroom Monitoring and Control System: This system is designed for local and remote monitoring and control of FFU (Fan Filter Unit) equipment to maintain the cleanliness of semiconductor cleanrooms. It enables quick and accurate monitoring of FFU operating status through wired communication, providing immediate alerts and corrective action capabilities to operators upon alarm generation. The system contributes to efficiently maintaining the clean state of large cleanroom areas with minimal personnel.

- Core Advantages

- As Korea's first research-oriented, technology-intensive SME, the company demonstrates strong capabilities in leading the localization of semiconductor equipment and commercializing new technologies, coupled with continuous investment and effort towards improving research productivity.As Korea's first research-oriented, technology-intensive SME, the company demonstrates strong capabilities in leading the localization of semiconductor equipment and commercializing new technologies, coupled with continuous investment and effort towards improving research productivity.

- The company has established a firm market position within the domestic semiconductor equipment industry through the development of advanced technologies in key areas such as cleanroom monitoring and control systems, Wafer Sorters, and Wafer Aligners.The company has established a firm market position within the domestic semiconductor equipment industry through the development of advanced technologies in key areas such as cleanroom monitoring and control systems, Wafer Sorters, and Wafer Aligners.

- Possessing a diverse lineup of automatic control device models, including PWM, MCUL, SFC, LIU, and LCU series, as well as semiconductor equipment like Wafer Sorters, Wafer Stockers, and EFEM, the company offers customized solutions that flexibly respond to various customer requirements.Possessing a diverse lineup of automatic control device models, including PWM, MCUL, SFC, LIU, and LCU series, as well as semiconductor equipment like Wafer Sorters, Wafer Stockers, and EFEM, the company offers customized solutions that flexibly respond to various customer requirements.

- The company provides advanced automatic control systems and possesses accumulated proprietary technical know-how in cleanroom monitoring and control systems, which efficiently manage the cleanliness of semiconductor cleanrooms.The company provides advanced automatic control systems and possesses accumulated proprietary technical know-how in cleanroom monitoring and control systems, which efficiently manage the cleanliness of semiconductor cleanrooms.

- The acquisition of multiple authoritative certifications, including CE certification (electromagnetic compatibility, safety), Venture Company certification, and Inno-Biz certification, externally validates the reliability of its products and the company's technological innovation.The acquisition of multiple authoritative certifications, including CE certification (electromagnetic compatibility, safety), Venture Company certification, and Inno-Biz certification, externally validates the reliability of its products and the company's technological innovation.

- Its history includes receiving the Presidential Award at the 2001 Venture Business Awards and extensive experience in developing multimedia and communication equipment such as USB capture packs, PDA TV receiver jackets, and Bluetooth protocol stacks, showcasing broad technological development capabilities.Its history includes receiving the Presidential Award at the 2001 Venture Business Awards and extensive experience in developing multimedia and communication equipment such as USB capture packs, PDA TV receiver jackets, and Bluetooth protocol stacks, showcasing broad technological development capabilities.

- The company's management philosophy emphasizes both technological innovation and customer satisfaction, achieved through customer and market-oriented R&D activities and substantial investment in human resources.The company's management philosophy emphasizes both technological innovation and customer satisfaction, achieved through customer and market-oriented R&D activities and substantial investment in human resources.

- Target Industrie

- Semiconductor manufacturingSemiconductor manufacturing

- Central monitoring system construction industryCentral monitoring system construction industry

- Multimedia device manufacturingMultimedia device manufacturing

- LCD equipment-related industryLCD equipment-related industry

- Cleanroom facility construction and electrical engineering sectorsCleanroom facility construction and electrical engineering sectors

- Major Markets

- South KoreaSouth Korea

- Certifications/Patents

- CE Certification (EMC, Safety)CE Certification (EMC, Safety)

- Venture Company CertificationVenture Company Certification

- Inno-Biz CertificationInno-Biz Certification

- Presidential Award at the 2001 Venture Business AwardsPresidential Award at the 2001 Venture Business Awards

Introduction

Key Products

Location

59-3 Hwaam-dong, Yuseong District, Daejeon, South Korea

클릭하여 위치 살펴보기