K-SYSTEMS-TOBOL

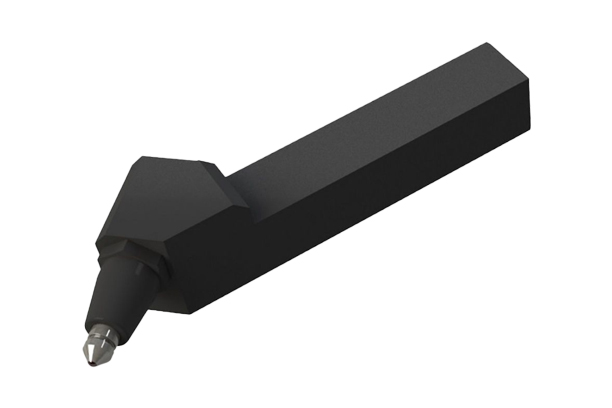

Burnishing Tool for Radius, Angle and Steplike Surfaces

모델명

시리즈

Diamond Burnishing Tools

구매 안내

아래는 참고용 정보이므로 세부 조건은 반드시 제조사/판매자에게 문의 바랍니다.

결제 방법

제조사/판매자에게 문의 바랍니다.

납기 정보

제조사/판매자에게 문의 바랍니다.

배송 정보

제조사/판매자에게 문의 바랍니다.

원산지

제조사/판매자에게 문의 바랍니다.

제품 상세 설명

Sensor-Tool ST7-25 diamond burnishing tools

USED FOR BURNISHING RADII AND ANGLE, STEPLIKE SHAFTS BURNISHING TOOL

Supplied in 2 versions

ST7-25L for processing parts in direction from rear center towards the chuck

ST7-25R for processing parts in direction from the chuck towards rear center

Used for finishing surface treatment of parts

The shape of the part is a cylinder, bodies of rotation

The diameter of the workpiece starting from 8 mm and higher

Metric square toolholders 20x20, 25x25 (as well as the size of the customer)

Inch toolholders 0.625"x0.625" 0.750"x0,750" 1.00"x1.00"

Natural diamond (ND)

The tool is used for finishing, finishing and strengthening and nanostructuring smoothing

Migration to other technical processes is possible only in a dynamometric device which is purchased separately.

The tool completely replaces the grinding and polishing area. High-precision diamond tools.

At finishing and finishing-hardening processing, smoothing of roughness is provided up to Ra = 0.2 ... 0.05 micron;

with nanostructuring treatment - up to Ra = 0.32 ... 0.12 microns.

Hardening of the surface layer is provided 1.3 ... 2 times relative to the initial state.

It is used on CNC machines and universal machines capable of finishing turning.

Comes with a remote cooling module. The module is characterized by zero coolant flow.

Does not have the ability to install from the tool shop !!!

Example of parts - hydraulic cylinder rods, valve spindles, heels of submersible pumps, shafts, sleeves, bearings, bushings, crankshafts, valves.

High-precision diamond tools. Metal burnishing.

lower processing costs

lower processing costs

reduction of processing costs

cost reduction for Metalworking

cost-cutting tools

cost-cutting tool

chipless processing

Metal processing without chip removal

cut back on metalworking costs

auxiliary time reduction

Reducing production costs

metalworking quality improvement

stress relief

Reducing production costs

lower direct costs for cutting tools

lower direct costs for grinding and polishing

Reduced set-up time

Reduced set-up time

cold working without chip removal

economy of scale

operational excellence

The quality of chrome plating can be improved by diamond smoothing its surface. This treatment compacts the surface layer and eliminates the tightness of tight joints of chrome-plated parts due to the presence of microcracks in chrome.