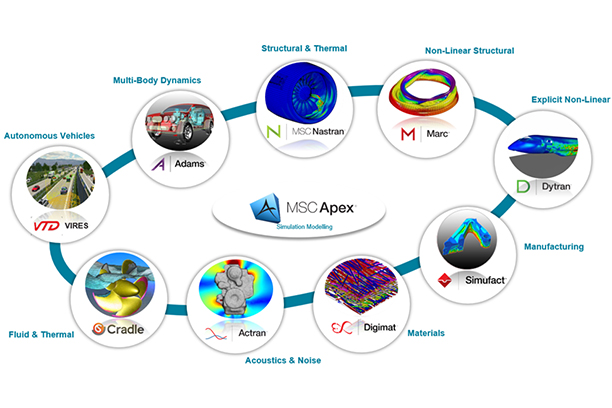

시뮬레이션 소프트웨어 공급업체, 구조, 다물체 동역학, 음향/소음, 비선형, 복합재료 해석 등 시뮬레이션 분야

내구성 측면에서의 설계검증 - 보증수리 감소, 안전성 향상 및 비용 절감

설계 및 개발 프로세스에서 가장 어려운 난제중의 하나는 파괴가 일어나는 한계 시간을 예측하는 것입니다. 구조물이 어떻게 파손될 것인가에 대한 지식 없이 안전성을 향상시키는 것은 어려운 일입니다. 또한 모든 발생 가능한 파손 시나리오에 대해 물리적인 시험을 수행하는 것도 비용 측면에서 보면 불가능하고 할 수 있습니다. 이런 이유로, FEA 기법에 의한 내구해석은 설계 프로세스에서 점점 확대 적용되고 있습니다. 해석은 이제 내구수명 산출에 국한되지 않고, 안전한 허용응력, 보증수리 한계 곡선들, 고온 환경 영향, 제조공정 프로세스 및 제작 응력 등 다양한 결과를 산출해 주고 있습니다.

MSC Software는 시간 영역 및 주파수 영역의 하중 조건을 조합하여 제품 수명을 정확하게 예측할 수 있는 FEA 기반의 내구 및 피로 문제에 대한 다양한 솔루션을 제공하고 있습니다.

MSC Software 제품은 다양한 내구성 해석에 사용되고 있습니다:

- 고주파 (S-N) 응력-수명 피로해석

- 저주파 (E-N) 변형율-수명 피로해석

- Neuber 및 기타 소성 보정 방법

- Paris를 이용한 균열 시작 및 진전 해석

- "가장 취약부위" 규명

- 변형 및 파손 해석

- 시험-해석 확인 - 가상 스트레인게이지

- Palmgren-Miner룰을 이용한 손상 누적

- 회전체 시스템 피로해석

- 랜덤 하중을 적용한 진동 피로해석

- 점용접 피로 및 연속용접 피로해석

- 전통적 "용접 표준법규" 에의한 피로해석

- 재료 파괴 예측

- 비례하지 않는, 다축응력 상태

- 다중 동시 및 다중 이벤트 Duty Cycle 피로해석

- 안전율(Safety factor) 해석

MSC Software 솔루션은 다양한 부품들의 내구성 분석에 사용됩니다:

Aerospace: 날개, 판넬, 엔진 날개, 휠, 리벳, 접합, 가진기, 변속기 부품, 밸브, 랜딩기어, 엔진 흡입구, 유압 변속 시스템.

Automotive: 기어, 용접, 샤시, 서스펜션, 리벳, 볼트, 휠, 크랭크 축, 컨넥팅 로드, 피스톤, 전체 차량 시스템.

Biomedical: 스텐트, 보철, 치과 임플란트, 엉덩이 임플란트, 무릎 임플란트.

Energy: 파이프, 압력용기, 굴착기, 제어 및 안전 밸브, 용접, 팬, 터빈, 풍력 터빈, 해양 플랫폼, 기어.

Electronics: 납땜, 연납, PCB, 가진기, 전자 랙 및 하우징 어셈블리.

Consumer Products: 차폐, 팬, 연결요소, 강선, 밸브, 자전기 페달, 운동기구.

Machinery: 기어, 벨트, 밸브, 차폐, 파이프, 튜브.

MSC Software is used to analyze durability of various types of components:

Aerospace: Wings, panels, engine blades, wheels, rivets, bondings, actuators, transmission components, valves, landing gear, nacelles, fluid transmission systems.

Automotive: Gears, welds, chassis, suspension, rivets, bolts, wheels, crankshaft, connecting rods, pistons, wheels, full body systems.

Biomedical: Stents, prosthetics, dental implants, hip implants, knee implants.

Energy: Pipes, pressure, vessel, drilling equipment, control and safety valves, welds, fans, turbines, wind turbines, offshore platforms, gears.

Electronics: Solder, lead wires, PCB, actuators, electronic racks and housing assemblies.

Consumer Products: Seals, fans, connectors, wires, valves, bicycle pedals, exercise equipment.

Machinery: Gears, belts, valves, seals, pipes and tubes.

Nastran Embedded Fatigue (NEF)

An entirely new concept for CAE based fatigue calculations.

NEF enables fatigue analysis to be performed as an integral part of stress analysis and not as a post processing task. This improves current practices which can be cumbersome and time consuming. NEF revolutionizes the way current calculations are done because there is a dramatic reduction in the number of miscellaneous files that have to be managed (improved durability management) and a corresponding reduction in the overall process time a large job can take.

With Nastran Embedded Fatigue (NEF), large stress (intermediate) files are no longer be needed. This eliminates the need for time consuming file transfer, reduces memory requirements, and enables fatigue computations to be performed faster in memory with use of less disk space. In this way full body fatigue calculations for large models are made possible.

Nastran Embedded Vibration Fatigue (NEVF)

NEVF enables users to perform the fatigue analysis in frequency domain with techniques that are often used for dynamic structural analyses. This computationally efficient procedure provides life estimates orders of magnitude faster with minimal loss in accuracy, while using only a small fraction of system resources compared to traditional methods. Frequency domain methods also offer quality results for complex load histories, which could be even random in nature.

Engineers can perform vibration fatigue studies with any of the following commonly used loading conditions:

- Single-input random load with or without static stress offset

- Multi-load random input including cross-correlation with or without static stress offset

- Deterministic loading (single sine waves and narrow bands)

- Harmonic loading (multiple simultaneously applied sine waves)

- Sine and narrow band sweeps

- Duty Cycles: All of the above loading types can be assembled in to load events and sequences to make up realistic duty cycles.

Interactive GUI Based Fatigue Analysis

MSC Fatigue is the most advanced, full featured durability product available in the marketplace.

Its advanced fatigue life estimation program allows users to perform comprehensive fatigue analysis with the same FE results that are used for stress analysis. The environment seamlessly enables CAE, dynamic analysis and durability to be managed in a single interface. It includes advanced modules developed by MSC Software over a 20 year period as well as more recent modules developed as part of the nCode DesignLife suite of programs.

MSC Fatigue sits fully within Patran , thus allowing access to the highly powerful pre and post processing capabilities within this advanced modelling environment.

Nonlinear Crack Propagation Capability

Comprehensive set of failure models suited for several material classes, including ductile, brittle, composites, elastomers, and concrete are available in Marc FEA solver. Robust crack propagation capability enables engineers to better grasp the failure mechanisms and device appropriate methods to avoid catastrophic failures.

This capability within Marc, as well as less sophisticated capabilities within Nastran, are also suitable ways to generate the crack propagation Compliance Functions that are needed by the crack growth (fatigue) tool which is part of MSC Fatigue

Virtual Loads and Multi Body Dynamic Systems

Adams/Durability, part of the Adams suite of software, extends the traditional test-based durability design process into the virtual world. With Adams/Durability, you can simulate a durability duty cycle and write out component load histories and drive a durability test rig using output data in RPC III Format or DAC Format. You can visualize stress and detect hot spots in flexible or rigid components, and you can improve component design by interfacing with fatigue life prediction programs.

In this way Adams is an essential tool for creating the FE loading time histories needed by either MSC Fatigue or Nastran Embedded Fatigue and both these products have ready made links to Adams to accommodate this integration.

Accurate Material Data

Accurate materials data is an essential part of any fatigue life calculation. MSC Software has recently formed a partnership with HBM nCode UK Ltd to provide a comprehensive, fast and competitively priced service for providing accurate material data. HBM nCode enables fatigue life prediction from virtual simulations, making it possible to perform durability assessment up front to avoid costly design changes.

Sometimes numerical modelling of material properties for fatigue can avoid the need to do so much experimental testing and Digimat provides a numerical modelling approach for this.

World Class Training and Engineering Services

MSC Software is able to utilize some of the worlds leading experts for the provision of both fatigue training classes and engineering services. Fatigue training can either be software focused (PAT319) or technology focused (NAS319). MSC Software can even offer a bespoke Durability Management Quick Start Project (NAS399) aimed at users currently employing GUI based fatigue analysis processes who want to switch to a solver embedded approach.

Related Products:

- Actran Acoustics 강력한 음향 시뮬레이션 소프트웨어

- Adams 다물체 동역학 시뮬레이션

- Digimat 비선형 멀티 스케일 재료 및 구조 모델링 플랫폼

- Marc 고급 비선형 시뮬레이션 솔루션

- MSC Fatigue 유한요소 기법의 내구해석 솔루션

- MSC Nastran 구조 & 다분야 통합 해석

- Patran FEA 솔버를 위한 Pre/Post 솔루션

- SimManager 시뮬레이션 프로세스 & 데이터 관리