This product is manufactured by

SM PLATEK

Manufacturer information

SM PLATEK

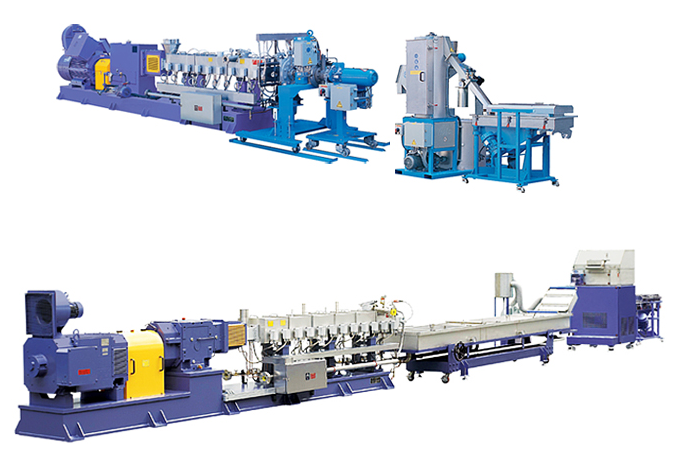

Manufacturer of twin screw extruder for plastic processing

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SM PLATEK

Product Type

Machine

Brand

-

SKU

14504

Product Name

Twin Screw Extruder Compounding System

Model Name

TEK-Series

Size

-

Weight

-

Product Details