This product is manufactured by

MSC SOFTWARE

Manufacturer information

MSC SOFTWARE

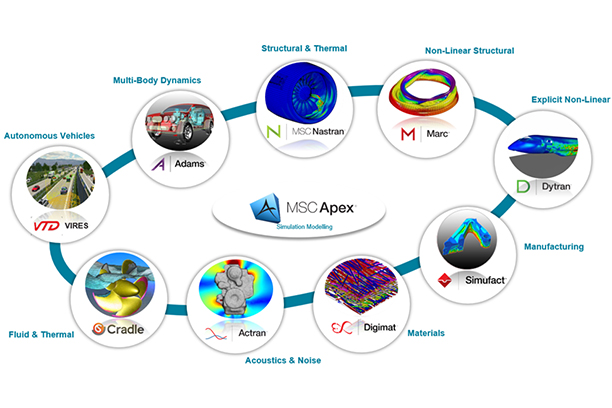

Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

MSC SOFTWARE

Product Type

Machine

Brand

-

SKU

118554

Product Name

Marc

Model Name

-

Size

-

Weight

-

Product Details

More products

MSC NastranMSC Nastran Embedded Vibration Fatigue

MSC NastranMSC Nastran Embedded Fatigue

MSC NastranMSC Nastran Advanced Nonlinear Analysis

SimufactSimufact Welding

SimufactSimufact Forming

SimufactSimufact Additive

AdamsAdams Real Time

AdamsAdams MaxFlex

AdamsFlexible Multibody Systems in Adams

AdamsAdams Car

AdamsAdams Machinery

ActranActran VI

ActranActran DGM

ActranActran TM

ActranActran SEA

ActranActran for Trimmed Body

1/4