M&C ENGINEERING

Description

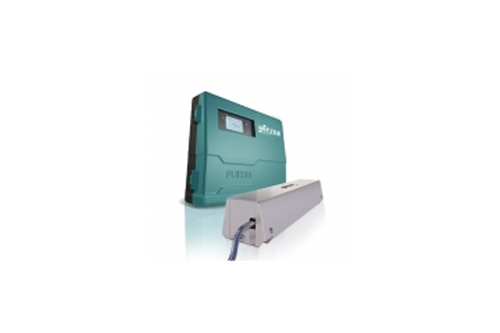

Transmitter for permanent outdoor wall or pipe mounting

Features

- Exact and highly reliable bidirectional clamp-on volume and mass flow measurement

- Installation and startup do not require any pipe work nor any process interruptions

- High measurement accuracy even at very low as well as very high flow rates and independent of the flow direction (bidirectional)

- Possibility to measure thermal energy quantities using clampon or inline temperature probes

- Automatic loading of calibration data and transducer recognition

- Bidirectional communication and support of common bus technologies (Profibus PA, Foundation Fieldbus, HART, Modbus, BACnet)

- Advanced self-diagnosis and possibilities for event based triggering of data recording for the supervision and control of critical processes

- Transmitter and transducers for use in hazardous areas are available

- Transmitter and transducers are separately calibrated (traceable to national standards)

- Transducers available for a wide range of inner pipe diameters and fluid temperatures -328 to +1112 °F

- The measurement is zero point stable, drift free and independent of pipe material, process pressure, process temperature and process fluid Applications

Advantages

No process interruption for installation, no pipe modification necessary - maintenance-free (no need for frequent work in hazardous areas)

Certified for operation within hazardous areas (ATEX / IECEx Zone 2 and FMc Class I, Div. 2 certified)

Fast measuring dynamics (output of measurement data every 10ms), capturing highly pulsating flows Reliable measurements of slurries or liquids with gaseous entrainments (>10% of total volume)

High operational safety with no risk of leaks

Independent of pipe material, diameter, wall thickness and internal pressure and temperature

Accurate and repeatable measurement readings - even at extremely low flow rates (high turndown ratio)

Highly cost efficient in comparison to wetted instrumentation

Every measurement system is pre-calibrated in-house (traceable to national standards) and delivered with a calibration certificate

Matched transducers, integrated temperature compensation (according to ANSI/ASME MFC-5.1-2011 regulations) and advanced digital signal processing guarantee a high zero point stability and drift free measurement readings

Permanent coupling with unique couplant pads, FlexSpring secured mounting fixtures guarantee durable contact pressure also on heavily vibrating pipes

Bidirectional communication as well as remote set-up and diagnostic capabilities

Enabling complete monitoring of processes as well as supervision and control of critical operations

Applications

- Chemical industry

- Petrochemical industry

- Oil and gas industry

- Pharmaceutical industry

- Semiconductor industry

- Manufacturing industries

- Building technology/energy management

- Water and wastewater industry

- Mining industries