HITROL

Description

When HAPT Series is installed in a pipeline, it is called as stagnation pressure once the flow velocity in front of the HAPT Series becomes zero and the pressure difference between stagnation pressure and static pressure in the pipe is called as dynamic pressure. Dynamic pressure is related to the velocity of the fluid in the pipeline so the dynamic pressure can be calculated if the stagnation pressure and static pressure are measured.

Design of Element

HAPT Series is hydrodynamically designed with almost vibrationless shape to generate a constant pressure and to minimize a pull force of fluid. HAPT Series consists of one body and average dynamic pressure in the pipeline is transmitted through a tube and ports for pressure measurement. The pressure difference between stagnation pressure and static pressure is called as dynamic pressure and it is proportional to a square of flow rate according to the Bernoulli equation.

Advantages

- It is easy to install by insertion to the pipeline.

- Welding area for mounting hardware is small.

- Energy cost for the operating can be reduced due to low pressure loss.

- High accuracy can be verified by confirmation of Discharge Coefficient through the calibration at our national flow calibration system.

Specification

Calibration and Discharge Coefficient Determination

All of HAPT Series that is manufactured and supplied by Hitrol is calibrated with water at our liquid flow calibration system to determine the Discharge Coefficient (Cd) to verify the performance of the flow meter.

Component of Flow Measurement System

| Measurement of incompressible fluids | Measurement of compressible fluids |

|

① HAPT-1(2)F Flow Element ② 3-way or 5-way manifold valve ③ Differential pressure transmitter ④ Flow Computer or flow indicator |

① HAPT-1(2)F Flow Element ② 3-way or 5-way manifold valve ③ Differential pressure transmitter ④ Flow Computer or flow indicator ⑤ Pressure transmitter ⑤ Temperature Sensor (Pt 100Ω) or transmitter |

|

|

|

Maximum Differential Pressure and Flow Range (HAPT-1F)

Maximum Differential Pressure and Flow Range (HAPT-2F)

Pressure Taps Orientation

|

||

| Horizontal Piping | Vertical Piping | |

| Gases & Steam (with Seal Port) | Liquid & Steam (without Seal Port) | Liquid & Gas & Steam |

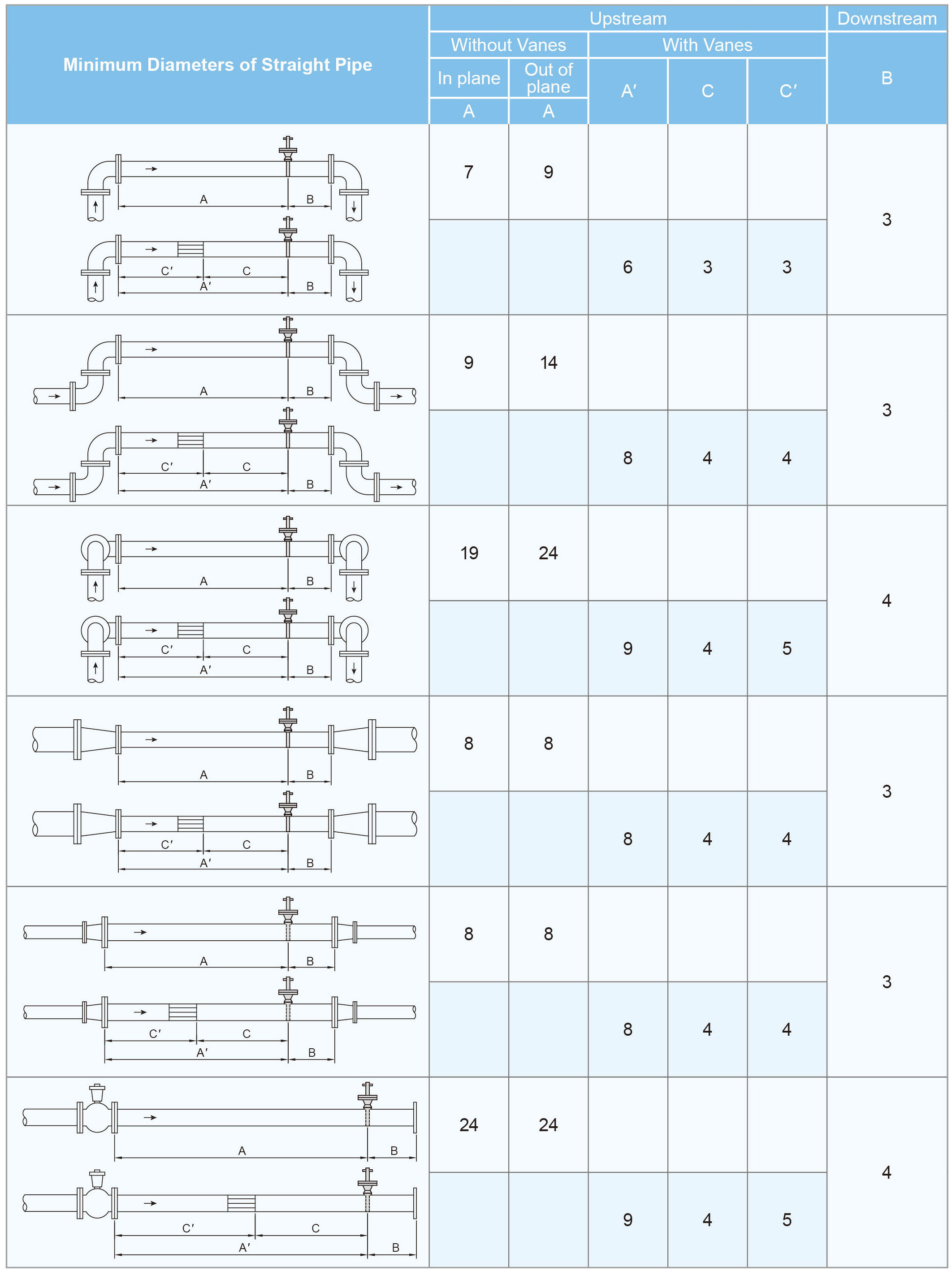

Installation Requirements

| Correct | Incorrect | |

| A |  |

|

| B |  |

|

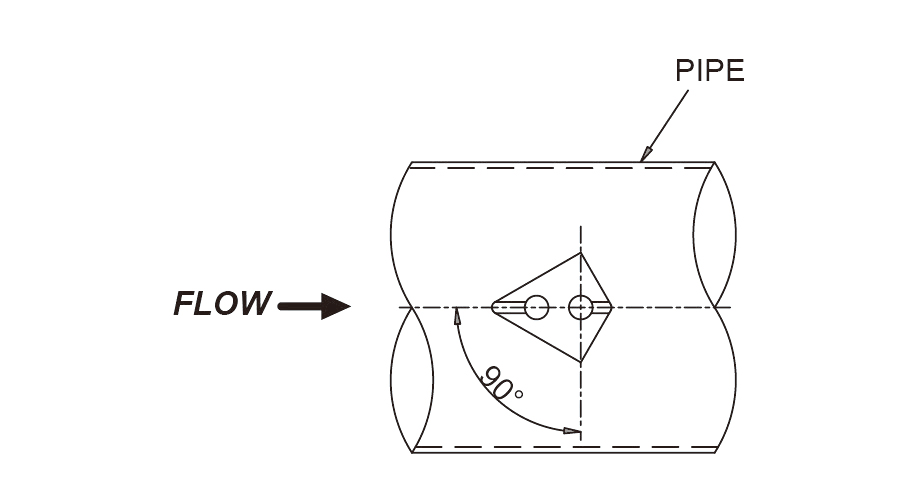

| The angle of installation shall be maintain the 90 degree between the averaging pitot tube and pipe as shown on Fig. A & B | ||

Required Straight Pipe Length