ECM TECHNOLOGIES

Description

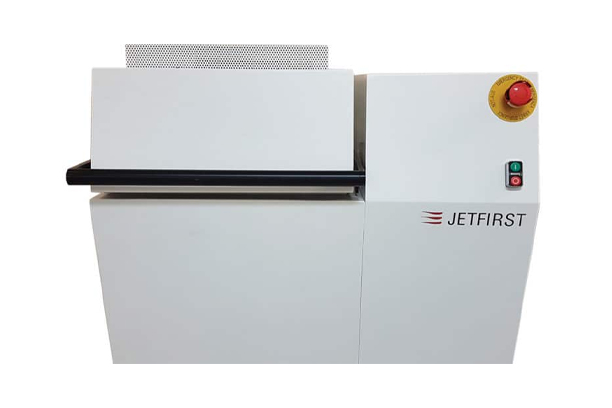

LAMP FURNACE - RAPID THERMAL PROCESSING

The ECM JetFirst system is a compact and robust lamp furnace suitable for the Rapid Thermal Annealig (RTA) of a wide range of material substrates and structures (Electronic Grade Si, steel glass, SoG c-Si, III-V, II-VI, Germanium, quartz, ceramics etc.) with a size from 100mm up to 300mm diameter.

This lamp furnace is equipped with a metallic water cooled reactor chamber and has therefore an ultra-low memory effect.

PLUS AND BENEFITS

The JetFirst system is a lamp furnace that has been developed to meet the requirements of universities and research laboratories. The temperature measurement control system provides accurate and repeatable thermal control across the temperature range. The lamp array, upper flange, and quartz window are mounted in a rotating top lid, giving full access to the chamber for easy loading and unloading of the wafer.

Silicon carbide coated graphite susceptors are available for the processing of various small samples and compound semi materials. A spare process chamber can be provided upon request to avoid cross contamination if several processes have to be performed in the same reactor. The high reliability and high performance characteristics of the JetFirst enable small-scale production.

The process can take place at atmospheric pressure or under vacuum. A PID system provides accurate and repeatable thermal control across the temperature range. RTP Process control is via computer, running PIMS dedicated supervisor that enables recipe programming and monitoring of the entire RTP system.

POSSIBLE APPLICATIONS

- Rapid thermal annealing (RTA)

- Rapid thermal oxidation (RTO)

- Rapid thermal nitridation (RTN)

- Rapid thermal diffusion (RTD)

- Crystallization, carbonization

- Contact alloying

- Selenization (with optional hardware)

EFFECTIVE DIMENSIONS

JETFIRST

- 100mm

- 200mm

- 300mm

OPTIONS

- Primary vacuum pump

- Secondary vacuum pump

- Process gas line

- Susceptor

- High temperature version

- Spare chamber

- Hydrogen configuration