ECM TECHNOLOGIES

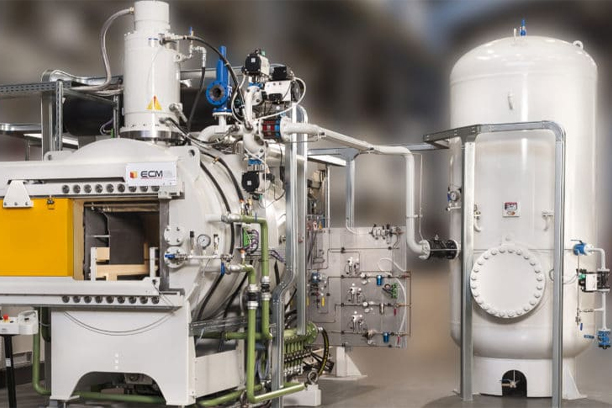

CARBURIZING FURNACES (ICBP® DUO)

Model

Series

CARBURIZING FURNACES

Transaction Process

Please contact the manufacturer/supplier.

Payment

Contact the manufacturer/supplier.

Delivery

Contact the manufacturer/supplier.

Shipment

Contact the manufacturer/supplier.

Origin

Contact the manufacturer/supplier.

Description

INNOVATION TO REPLACE INTEGRAL QUENCH & SEALED QUENCH FURNACES

Furnaces from the DUO range are made of a heating cell and of an integrated quenching cell. Quenching processes could be either in oil (cold or hot) or using gas with a maximal pressure of 20 bar. Both chambers are totally independant and separated by a vacuum tight door.

These furnaces replace batch atmospheric installations, sealed quench and IQ furnaces, for carburizing, carbonitriding, brazing & hardening applications.

PLUS AND BENEFITS

DUO furnaces are a great alternative to sealed quench furnaces and have singificant advantages. Indeed, heat treatments are done at higher temperatures and lead to a better treatment quality as well as shorter cycles, which results in an increased productivity.

These installations are also very convenient to integrate in production and / or machining lines. Their design limits heat losses, reduces CO2 emissions and cancels the risk of fire hazard since no flames are generated thanks to the use of vacuum. Moreover, DUO furnaces are electrically heated.

Electric heating has several other advantages such as the elimination of endo gas generators, which eases maintenance and avoids additional costs. Also, this heating method significantly ereduces gas consumption and emissions since gas injections are stricly limited to the process according to the kind of treatment needed. As an example, in the case of a carburizing process, gas injections only occur in the enrichment phase as “boosts” and during the quenching phase if gas queching is relevant.

Finally, the carbon footprint of these furnaces is considerably reduced compared to sealed quench furnaces and hence allows cleaner, more efficient and more sustainable heat treatments.

POSSIBLE APPLICATIONS

- Low pressure / vacuum carburizing

- Low pressure carbonitriding

- Quenching

- Case hardening

- Vacuum annealing

- Brazing

- Sintering

EFFECTIVE DIMENSIONS

| ICBP DUO 644 OIL / GAS QUENCHING |

|

| ICBP DUO 966 GAS QUENCHING |

|

| ICBP DUO 966 OIL QUENCHING |

|

| ICBP DUO 1299 OIL QUENCHING |

|

| MORE SIZES AVAILABLE : CONTACT US |

OPTIONS

- Compatible with

- AMS2750

- CQI9

- Inert gas convection

- Hot oil quenching

- Possibility to integrate the furnace and all peripherals within a heat treating line, made of: washing machine, preheating furnace, tempering, storage, transfer system, unloading…