Overview

- Summary

- Established in 1950, Namsun Machinery is a pioneer in the Korean machine tool industry, with a deep history predating its official inception. The company researches and produces high-quality milling, drilling, and boring machines based on over 60 years of accumulated technology and management know-how. Technical alliances with leading Japanese machine tool manufacturers enable the development of products that meet diverse customer demands. This global manufacturer supplies state-of-the-art, high-performance vertical, gantry, and 5-axis machining centers to both domestic and international markets. A broad product lineup, from general-purpose milling machines to advanced 5-axis machining centers, is a core strength.Established in 1950, Namsun Machinery is a pioneer in the Korean machine tool industry, with a deep history predating its official inception. The company researches and produces high-quality milling, drilling, and boring machines based on over 60 years of accumulated technology and management know-how. Technical alliances with leading Japanese machine tool manufacturers enable the development of products that meet diverse customer demands. This global manufacturer supplies state-of-the-art, high-performance vertical, gantry, and 5-axis machining centers to both domestic and international markets. A broad product lineup, from general-purpose milling machines to advanced 5-axis machining centers, is a core strength.

- Key Products/Technologies

- **CNC Milling (A-PRO MILL)**: A CNC milling machine specialized for metal and pattern processing, enabling non-cutting processing of non-ferrous materials and integrating milling, drilling, pocketing, and can cycle functions. It offers high-speed processing capabilities of 5,000rpm and combines the functions of both universal and CNC milling.**CNC Milling (A-PRO MILL)**: A CNC milling machine specialized for metal and pattern processing, enabling non-cutting processing of non-ferrous materials and integrating milling, drilling, pocketing, and can cycle functions. It offers high-speed processing capabilities of 5,000rpm and combines the functions of both universal and CNC milling.

- **Simultaneous 5-axis High Speed Machining Center (SPHINX-5X Series)**: The SPHINX-5X,53 model features a box-type crossrail structure for enhanced support against multi-directional resistance during 5-axis cutting, along with backlash elimination technology utilizing a table torque motor. It incorporates HSK, A63 built-in motors suitable for high-speed rotation. The SPHINX-5X,30 model allows selection between Heidenhain or Fanuc controls, boasts an integrated column and crossrail structure, and uses a Swiss ETEL torque motor for perfect backlash elimination, with an HSK A40 spindle for high-speed rotation.**Simultaneous 5-axis High Speed Machining Center (SPHINX-5X Series)**: The SPHINX-5X,53 model features a box-type crossrail structure for enhanced support against multi-directional resistance during 5-axis cutting, along with backlash elimination technology utilizing a table torque motor. It incorporates HSK, A63 built-in motors suitable for high-speed rotation. The SPHINX-5X,30 model allows selection between Heidenhain or Fanuc controls, boasts an integrated column and crossrail structure, and uses a Swiss ETEL torque motor for perfect backlash elimination, with an HSK A40 spindle for high-speed rotation.

- **Vertical Machining Center (SPACE 540, SPACE-430)**: The SPACE 540 model features a motor direct-drive spindle, a high-rigidity four-sided supported box-type bed surface structure, a high-precision machining control system (AICC, Data server equipped), and a powerful direct-coupled integral spindle structure.**Vertical Machining Center (SPACE 540, SPACE-430)**: The SPACE 540 model features a motor direct-drive spindle, a high-rigidity four-sided supported box-type bed surface structure, a high-precision machining control system (AICC, Data server equipped), and a powerful direct-coupled integral spindle structure.

- **Automatic Tool Change Milling Machine (NSM-A, NSM-T)**: The NSM-A is an automatic tool change vertical milling machine with a spindle speed of 5,000rpm. The NSM-T is a composite milling machine equipped with both vertical and horizontal spindles.**Automatic Tool Change Milling Machine (NSM-A, NSM-T)**: The NSM-A is an automatic tool change vertical milling machine with a spindle speed of 5,000rpm. The NSM-T is a composite milling machine equipped with both vertical and horizontal spindles.

- **Universal Equipment (NSL-Series, NSR-Series, NSB-100, NSM-V, NSM-H)**: The NSL-Series universal lathe offers powerful cutting ability and easy operation. The NSR-Series radial drilling machine (NSR-1160, NSR-1600, NSR-1750, NSR-2100) provides precision and power. The NSB-100 is a universal boring machine with the largest processing area in its class and powerful performance. The NSM-V is a powerful vertical milling machine, and the NSM-H is a powerful horizontal milling machine.**Universal Equipment (NSL-Series, NSR-Series, NSB-100, NSM-V, NSM-H)**: The NSL-Series universal lathe offers powerful cutting ability and easy operation. The NSR-Series radial drilling machine (NSR-1160, NSR-1600, NSR-1750, NSR-2100) provides precision and power. The NSB-100 is a universal boring machine with the largest processing area in its class and powerful performance. The NSM-V is a powerful vertical milling machine, and the NSM-H is a powerful horizontal milling machine.

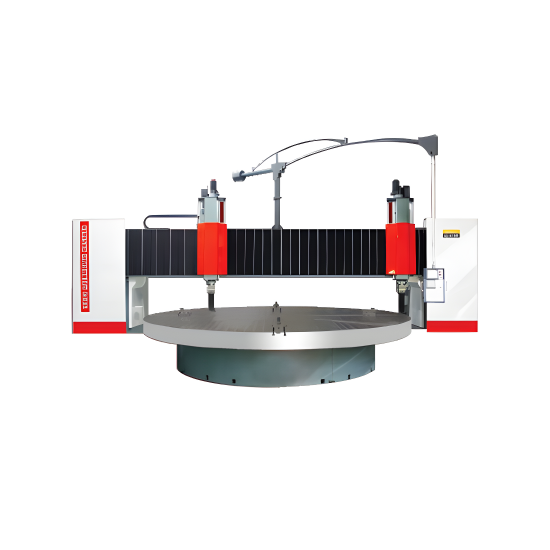

- **Ring Dedicated Processing Machine (NS-Ri 7585)**: A specialized machine for processing large ring components in the wind power industry, featuring two turning heads for simultaneous internal/external diameter machining and a hydrostatic table flotation system for smooth rotation.**Ring Dedicated Processing Machine (NS-Ri 7585)**: A specialized machine for processing large ring components in the wind power industry, featuring two turning heads for simultaneous internal/external diameter machining and a hydrostatic table flotation system for smooth rotation.

- Core Advantages

- A profound history dating back to 1950, preceding the dawn of the Korean machine tool industry, with over 60 years of accumulated unique technology and management know-how, establishing the company as a leader in precision machinery manufacturing and export.A profound history dating back to 1950, preceding the dawn of the Korean machine tool industry, with over 60 years of accumulated unique technology and management know-how, establishing the company as a leader in precision machinery manufacturing and export.

- Decades of technical alliances with leading Japanese machine tool manufacturers, enabling the production of high-quality products that meet diverse customer needs. Continuous R&D efforts ensure the ongoing supply of state-of-the-art, high-quality, high-performance vertical, gantry, and 5-axis machining centers to global markets.Decades of technical alliances with leading Japanese machine tool manufacturers, enabling the production of high-quality products that meet diverse customer needs. Continuous R&D efforts ensure the ongoing supply of state-of-the-art, high-quality, high-performance vertical, gantry, and 5-axis machining centers to global markets.

- A comprehensive product lineup, from universal milling, drilling, and boring machines to advanced 5-axis machining centers, with a customer-centric approach that involves understanding customer needs and providing prompt feedback for product development and customized solutions.A comprehensive product lineup, from universal milling, drilling, and boring machines to advanced 5-axis machining centers, with a customer-centric approach that involves understanding customer needs and providing prompt feedback for product development and customized solutions.

- A corporate philosophy committed to zero-defect perfectionism and ultra-precision, allowing no more than a 0.01% defect rate, ensuring high product quality and accuracy. The ability to supply products with functionality comparable to international competitors at 60-70% of import prices, offering significant cost competitiveness.A corporate philosophy committed to zero-defect perfectionism and ultra-precision, allowing no more than a 0.01% defect rate, ensuring high product quality and accuracy. The ability to supply products with functionality comparable to international competitors at 60-70% of import prices, offering significant cost competitiveness.

- Active export activities to global markets including the USA, Japan, China, Germany, Sweden, Russia, Switzerland, Canada, Australia, Singapore, and Israel, evidenced by achievements such as the '1 Million Dollar Export Tower Award' in 1997.Active export activities to global markets including the USA, Japan, China, Germany, Sweden, Russia, Switzerland, Canada, Australia, Singapore, and Israel, evidenced by achievements such as the '1 Million Dollar Export Tower Award' in 1997.

- Pioneering the development of Korea's first 5-axis machining center (SPHINX-5X) and receiving the Presidential Award at the Precision Technology Promotion Competition, solidifying its position as a technology leader. Furthermore, the development of specialized equipment like the NS-Ri 7585, a dedicated turning center for wind power components, showcases its capability in niche industrial applications.Pioneering the development of Korea's first 5-axis machining center (SPHINX-5X) and receiving the Presidential Award at the Precision Technology Promotion Competition, solidifying its position as a technology leader. Furthermore, the development of specialized equipment like the NS-Ri 7585, a dedicated turning center for wind power components, showcases its capability in niche industrial applications.

- Target Industrie

- **Metal Cutting and Processing Industry**: Broad application across the entire metal cutting and pattern processing industry, a core area of machine tools.**Metal Cutting and Processing Industry**: Broad application across the entire metal cutting and pattern processing industry, a core area of machine tools.

- **Automotive Parts Manufacturing Industry**: Utilization in the automotive parts manufacturing sector, where precision and high-performance machining are critical.**Automotive Parts Manufacturing Industry**: Utilization in the automotive parts manufacturing sector, where precision and high-performance machining are critical.

- **Aerospace Industry**: Contribution to the production of aerospace components, requiring ultra-precision machining technology.**Aerospace Industry**: Contribution to the production of aerospace components, requiring ultra-precision machining technology.

- **Heavy Industry and Shipbuilding Industry**: Application in heavy industry and shipbuilding sectors, demanding large component processing and high-rigidity operations.**Heavy Industry and Shipbuilding Industry**: Application in heavy industry and shipbuilding sectors, demanding large component processing and high-rigidity operations.

- **Wind Power Plant Industry**: Provision of specialized solutions for manufacturing key components in the wind power plant industry through its dedicated large ring component processing machine (NS-Ri 7585).**Wind Power Plant Industry**: Provision of specialized solutions for manufacturing key components in the wind power plant industry through its dedicated large ring component processing machine (NS-Ri 7585).

- **Casting Material Industry**: As one of the top 4 casting material manufacturers in Korea, supplying casting materials such as Grey Iron, FC250, and FC300 to major companies including Hyundai Heavy Industries and Doosan Infracore.**Casting Material Industry**: As one of the top 4 casting material manufacturers in Korea, supplying casting materials such as Grey Iron, FC250, and FC300 to major companies including Hyundai Heavy Industries and Doosan Infracore.

- Major Markets

- China, Japan, SingaporeChina, Japan, Singapore

- Germany, Sweden, Russia, SwitzerlandGermany, Sweden, Russia, Switzerland

- United States, CanadaUnited States, Canada

- AustraliaAustralia

- Certifications/Patents

- **Awards**: Recipient of the 1st Small and Medium Business Award (Minister of Trade, Industry and Energy) in 1991. Awarded the 1 Million Dollar Export Tower (Ministry of Trade, Industry and Energy) in 1997. Received the Presidential Award in the Precision Machinery category at the 34th Precision Technology Promotion Competition for its 5-axis machining center (SPHINX-5X) in 2004. Achieved 1st place in the Small and Medium Business category at the 14th National Precision Competition in 1985. Honored with the 1st Korea Science and Technology Meritorious Industrial Medal in 1987. Awarded a bronze medal at the National Quality Competition in 1994. Received a silver medal at the National Factory Quality Control Competition in 1992. Awarded a bronze medal at the International Design Excellence Awards (IDEA) in 2012.**Awards**: Recipient of the 1st Small and Medium Business Award (Minister of Trade, Industry and Energy) in 1991. Awarded the 1 Million Dollar Export Tower (Ministry of Trade, Industry and Energy) in 1997. Received the Presidential Award in the Precision Machinery category at the 34th Precision Technology Promotion Competition for its 5-axis machining center (SPHINX-5X) in 2004. Achieved 1st place in the Small and Medium Business category at the 14th National Precision Competition in 1985. Honored with the 1st Korea Science and Technology Meritorious Industrial Medal in 1987. Awarded a bronze medal at the National Quality Competition in 1994. Received a silver medal at the National Factory Quality Control Competition in 1992. Awarded a bronze medal at the International Design Excellence Awards (IDEA) in 2012.

- **Technological Competence**: Development of Korea's first 5-axis machining center and completion of the multi-face multi-angle machining center (SOLAR-A) in 1993. Development of the high-speed machining center 'NASU-520VH' in 2002. Development of the NSRI-7585, a dedicated turning center for wind power, in 2010. Continuous technology accumulation and product advancement through technical alliances with leading Japanese companies.**Technological Competence**: Development of Korea's first 5-axis machining center and completion of the multi-face multi-angle machining center (SOLAR-A) in 1993. Development of the high-speed machining center 'NASU-520VH' in 2002. Development of the NSRI-7585, a dedicated turning center for wind power, in 2010. Continuous technology accumulation and product advancement through technical alliances with leading Japanese companies.

- **Official Patent Details**: No specific official patent details are publicly confirmed.**Official Patent Details**: No specific official patent details are publicly confirmed.

Introduction

Key Products

Location

17 Daejeon-ro 1331beon-gil, Daedeok-gu, Daejeon, South Korea

클릭하여 위치 살펴보기